- Joined

- Jan 11, 2018

- Messages

- 308

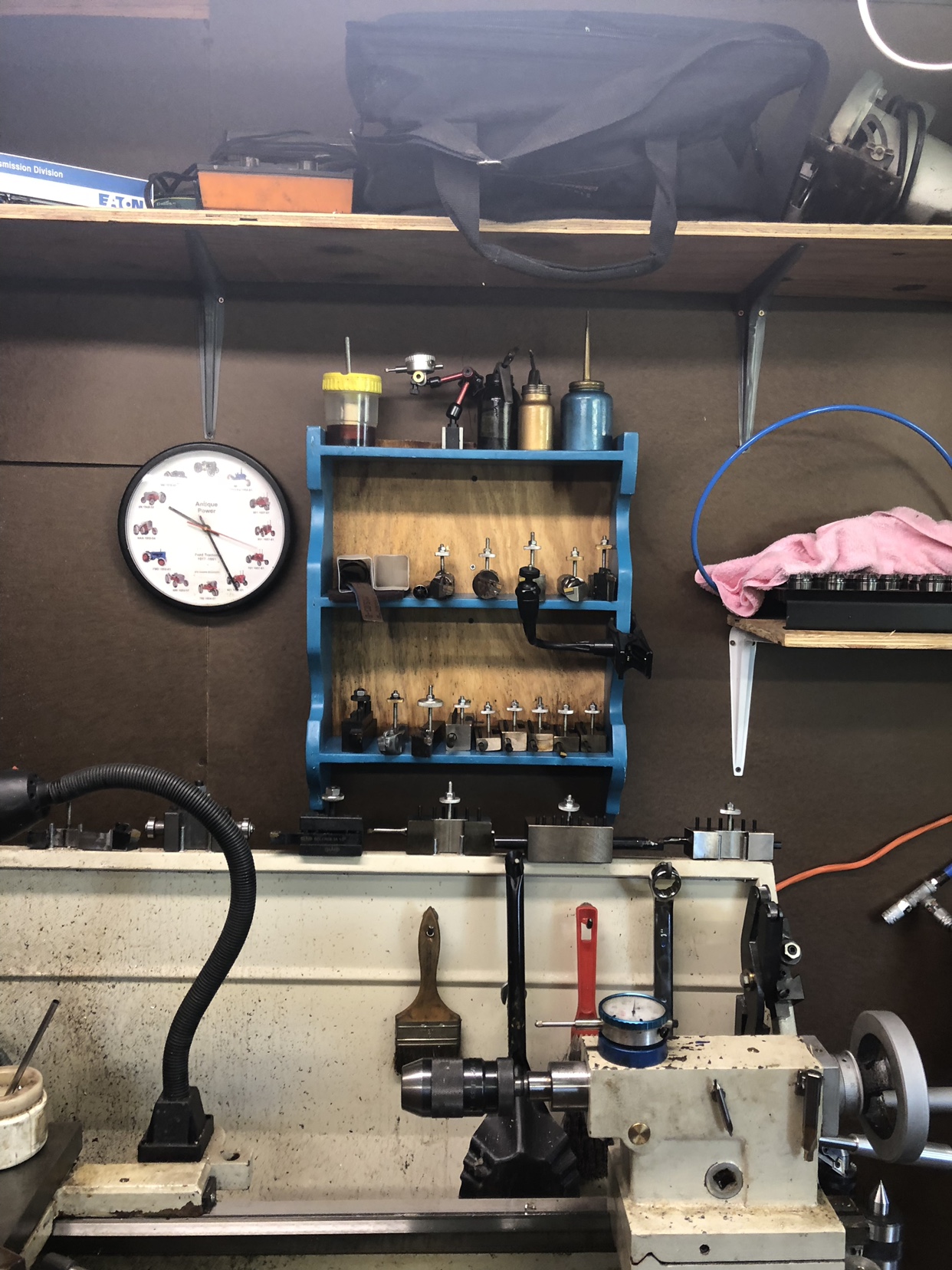

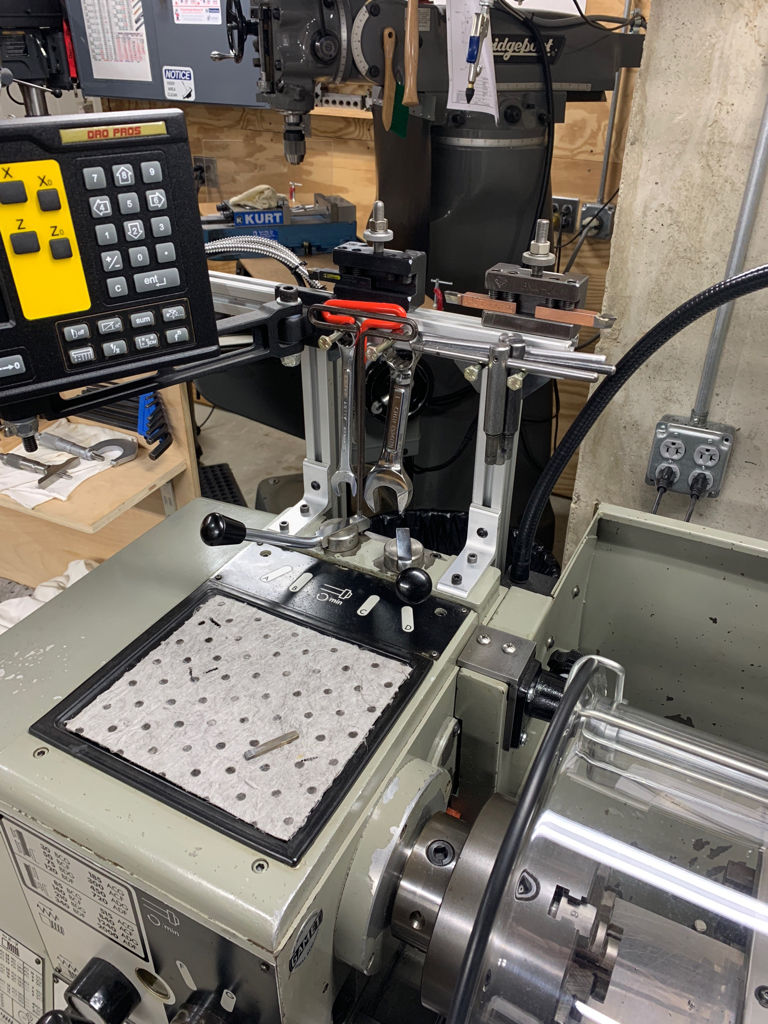

Ever since I bought my latest lathe I've had the toolholders sitting in the chip pan. I'm tired of cleaning way oil and chips off of them so I decided to make a rack for them. I have a piece of 1010 rail for the rack, so I just needed to make some toolholder brackets. I drew these up in Fusion 360 and milled them on my CNC converted G0704 mill. I made 20 of them even though I only have 10 toolholders at the moment. It's always easier to make a few extra the first time than to have to redo the set ups later.