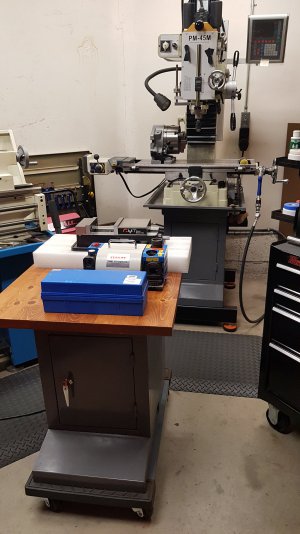

I assume it’s the same stand as the Grizzly 0705 has. I don’t like it. You gotta get on your knees to look inside of it. It’s made of sheet metal, so it has some reverb. It’s too short, unless a person wants to sit down while using it, which I don’t. There’s no drawers in it, so that’s completely unhandy as well. There is a thread around here somewhere highlighting the stands other users have built. Much better stands can be found there...of course then you have to build it.