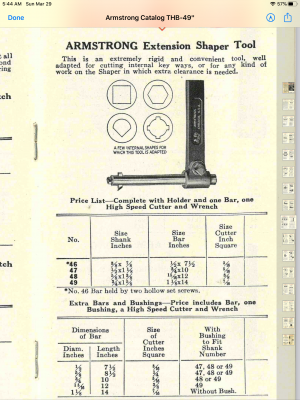

My Rhodes 7” shaper came with a little stubby lantern tool holder. The lantern is a larger diameter than my unused lantern holders from the South Bend holders so I’ll have to make a Lantern tool holder if I want to use the extensions tool hold the tool bits. Actually, I figured I rough shape two lanterns.. shaper and lathe.