- Joined

- Nov 15, 2016

- Messages

- 943

Here's a little program, gearspec, that is really helpful when working with gears, whether making them or measuring them to find out what you got.

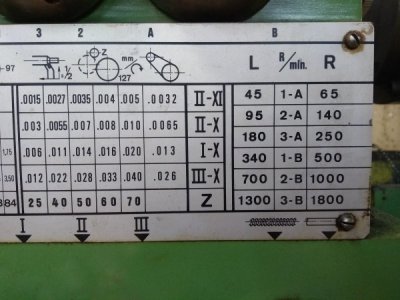

This one LatheGears gives combinations that may not be listed and also tells you what is needed without spending 1/2 hour with a calculator or pencil & paper.

Also have a look at what your feed rates are, in the fine pitches sometimes one will be what you need or so close that it can be used in a pinch for some work.

This one LatheGears gives combinations that may not be listed and also tells you what is needed without spending 1/2 hour with a calculator or pencil & paper.

Also have a look at what your feed rates are, in the fine pitches sometimes one will be what you need or so close that it can be used in a pinch for some work.