- Joined

- Nov 26, 2018

- Messages

- 261

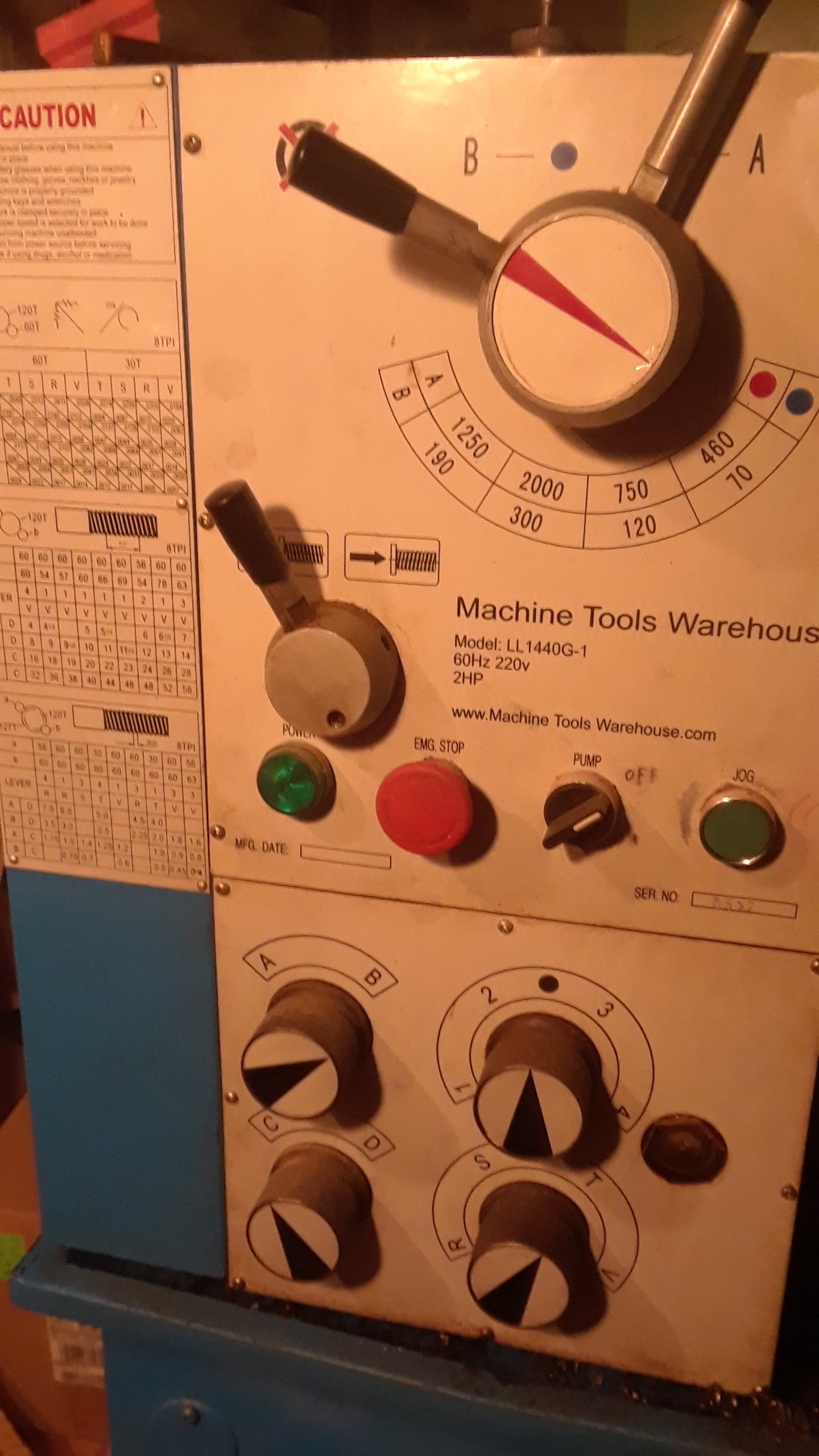

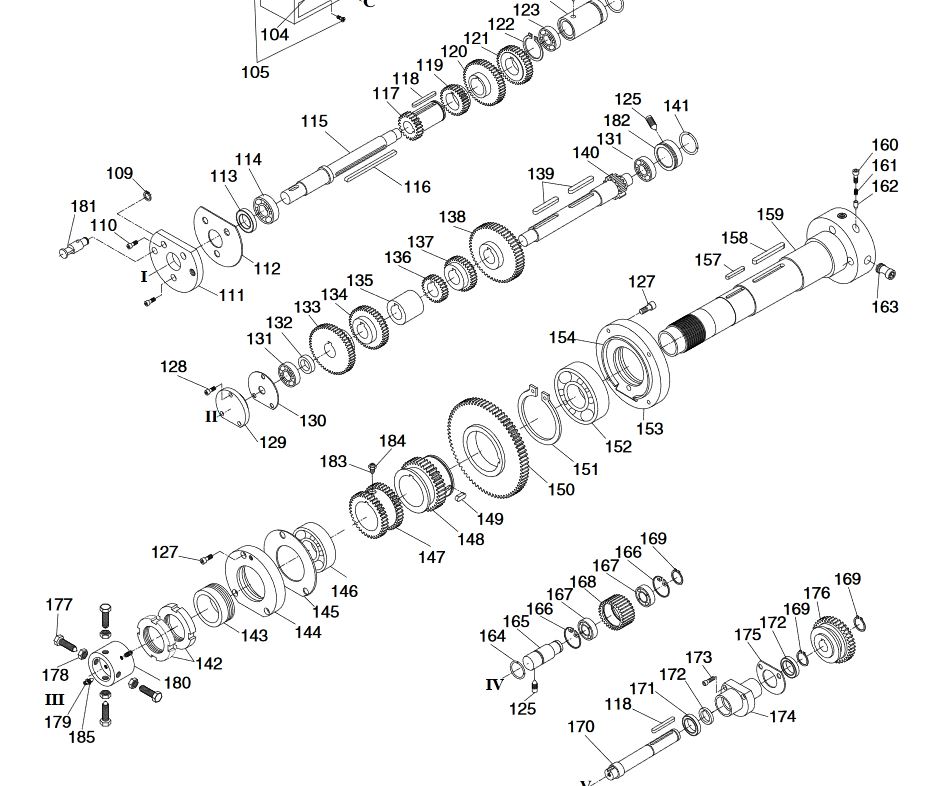

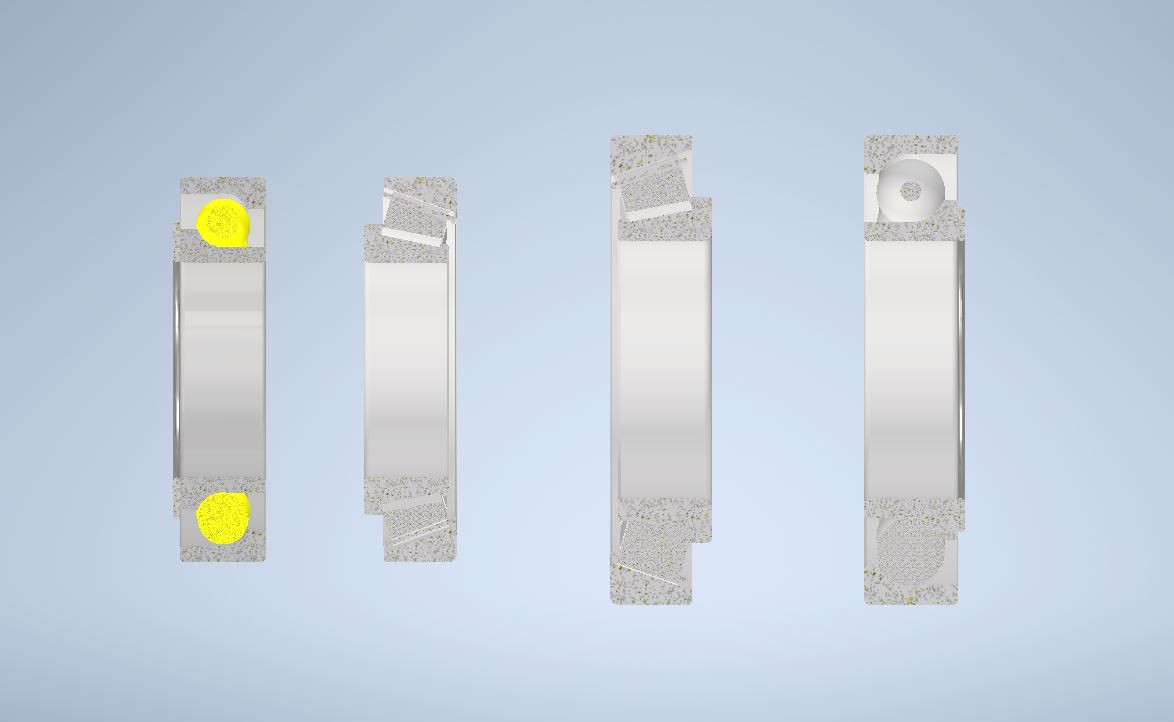

As the title suggests I intend to change the spindle bearings in my 1440 lathe. Mainly because I'm spoiled by the mas turn and colchester lathe at work, surface finish and parallelism are at a different league from my home lathe. So I spent some time and did some research on the size of bearings needed. The grizzly equivalent uses the bearings listed below and I would for quoting purposes for myself assume that theses are the same, I will of course take the machine apart to confirm bearing sizes. Finding high precision bearings in tapered roller bearings is a challenge, online distributes frequently display on their web site class 0 or class K, bearings in the appropriate size having 10-20 microns of runout. Usable for say a counter shaft used for power transition, though hardly satisfactory for a lathe. It is also about the amount of free play I have in my spindle bearings, so it is suggesting that the manufacturer very well could have used these bearings.

So what are my options, ISO 492 Class 4 tapered roller bearings are hard to find listed let alone get a hold of, though equivalent Od and Id angular contact bearings are available from multiple manufacturers. The lost thickness can be made up by ground shims or modifying the head stock spindle retaining system. I would obviously need to take apart the head stock to see how best this be done, the shoulders of the bearings don't exactly match. The load limitations of these bearings is near equivalent. I'm just in the speculation phase of this.

Is it worth changing the spindle bearings to my lathe? Does the accuracy of the machine other sliding component take full advantage of the ABEC- 7 bearings.? This is the machine that I learned how to scrape dove tail ways, so the compound and cross slide are glass smooth with out wiggle. Scraping the bed ways would be on my short list, if successful I would then have a tool room lathe minus the ridged castings.

(The listed bearing dimensions are not confirmed to fit any lathe.)

30210

Dimensions - d (inside diameter) 50mm

Dimensions - D (outside diameter) 90mm

Dimensions - B (width) 21.75mm

$68.92 EACH

30212

Dimensions - d (inside diameter) 60mm

Dimensions - D (outside diameter) 110mm

Dimensions - B (width) 23.75mm

7212 CDGA/P4A

Dimensions - d (inside diameter) 60mm

Dimensions - D (outside diameter) 110mm

Dimensions - B (width) 22mm

$495.95 EACH

7210 CDGA/P4A

Dimensions - d (inside diameter) 50mm

Dimensions - D (outside diameter) 90mm

Dimensions - B (width) 20mm

$362.97 EACH

https://www.timken.com/wp-content/u...ion-Tapered-Roller-Bearings-Brochure_5722.pdf

So what are my options, ISO 492 Class 4 tapered roller bearings are hard to find listed let alone get a hold of, though equivalent Od and Id angular contact bearings are available from multiple manufacturers. The lost thickness can be made up by ground shims or modifying the head stock spindle retaining system. I would obviously need to take apart the head stock to see how best this be done, the shoulders of the bearings don't exactly match. The load limitations of these bearings is near equivalent. I'm just in the speculation phase of this.

Is it worth changing the spindle bearings to my lathe? Does the accuracy of the machine other sliding component take full advantage of the ABEC- 7 bearings.? This is the machine that I learned how to scrape dove tail ways, so the compound and cross slide are glass smooth with out wiggle. Scraping the bed ways would be on my short list, if successful I would then have a tool room lathe minus the ridged castings.

(The listed bearing dimensions are not confirmed to fit any lathe.)

30210

Dimensions - d (inside diameter) 50mm

Dimensions - D (outside diameter) 90mm

Dimensions - B (width) 21.75mm

$68.92 EACH

30212

Dimensions - d (inside diameter) 60mm

Dimensions - D (outside diameter) 110mm

Dimensions - B (width) 23.75mm

7212 CDGA/P4A

Dimensions - d (inside diameter) 60mm

Dimensions - D (outside diameter) 110mm

Dimensions - B (width) 22mm

$495.95 EACH

7210 CDGA/P4A

Dimensions - d (inside diameter) 50mm

Dimensions - D (outside diameter) 90mm

Dimensions - B (width) 20mm

$362.97 EACH

https://www.timken.com/wp-content/u...ion-Tapered-Roller-Bearings-Brochure_5722.pdf