- Joined

- Jan 2, 2019

- Messages

- 6,526

Hi,

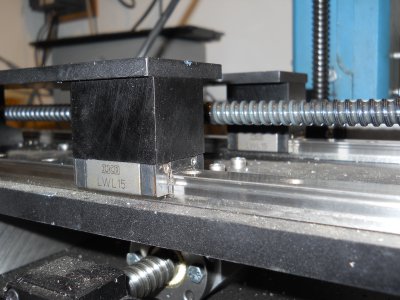

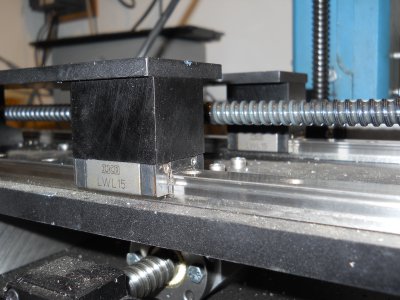

My x-axis is kinda sticky and rough feeling, leading the coupling to slip. I took the machine apart but now I'm at a standstill figuring out how to proceed. I have IKO LWL-15 bearings. https://www.ikont.co.jp/global_data/download/pdf_catalog/cat5510.1ML.pdf

Their documentation is a little ambiguous about lubrication, referring to ports I don't have on these units (I have four that I want to service). My gut instinct is to take a can of brake cleaner and squirt them out followed by some spray lithium grease. I figure some of you must have dealt with this before so please let me know if I'm gonna mess anything up here.

I'd rather spend my money on bellows to keep them clean than replacing these expensive little buggers.

Thanks,

John

My x-axis is kinda sticky and rough feeling, leading the coupling to slip. I took the machine apart but now I'm at a standstill figuring out how to proceed. I have IKO LWL-15 bearings. https://www.ikont.co.jp/global_data/download/pdf_catalog/cat5510.1ML.pdf

Their documentation is a little ambiguous about lubrication, referring to ports I don't have on these units (I have four that I want to service). My gut instinct is to take a can of brake cleaner and squirt them out followed by some spray lithium grease. I figure some of you must have dealt with this before so please let me know if I'm gonna mess anything up here.

I'd rather spend my money on bellows to keep them clean than replacing these expensive little buggers.

Thanks,

John