I would do it in two cuts, but remembering that on the finish cut, at least two teeth are engaged in the cut to avoid the cutter hammering, table jumping, and liable to knock a tooth out of it. If the cutter module or DP is fine enough, I prefer to cut the spaces in one cut, to full depth, so like so many things in life, it depends ---- on the machine doing the cutting, the material, and the rigidity of the setup, to name several factors.

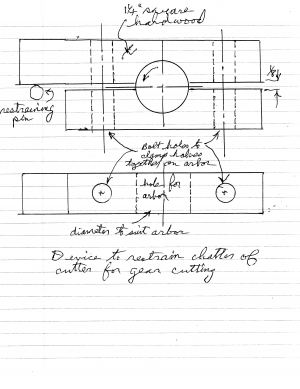

Bottom line, taking numerous small cuts is generally not a good thing, I have a few cutters with missing teeth to prove the point. One thing that I did when cutting gears with my 1906 vintage #2 B&S mill was to make a sort of brake to fit over the arbor collars that was clamped down over the collars tight enough to stop the hammering of the cutter, of course, it was anchored against rotating on its own against a stud on the arbor support casting.

It seems my brain doesn't want to work tonight the way I want it to. I'll appreciate the drawing. Sorry John. I feel a bit silly now

It seems my brain doesn't want to work tonight the way I want it to. I'll appreciate the drawing. Sorry John. I feel a bit silly now