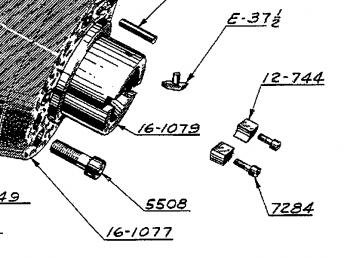

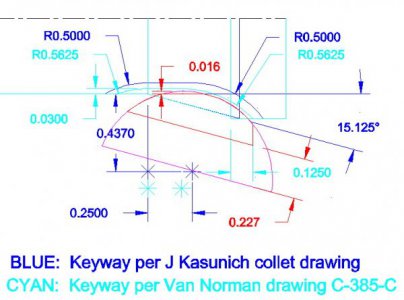

I have not had much time to play with my "new" VN12 but in looking at it I have started to develop questions. I'm wondering if you other VN folks might have some of the answers. Keep in mind I'm completely new to milling so..... you get the picture. Too many questions for one post so let me start with this one. My spindle collet positioning "key" seems to have been completely worn or ground down. From a very grainy copy's of an exploded parts diagram it seems like it should be easily removed. Any thoughts on how this is attached?

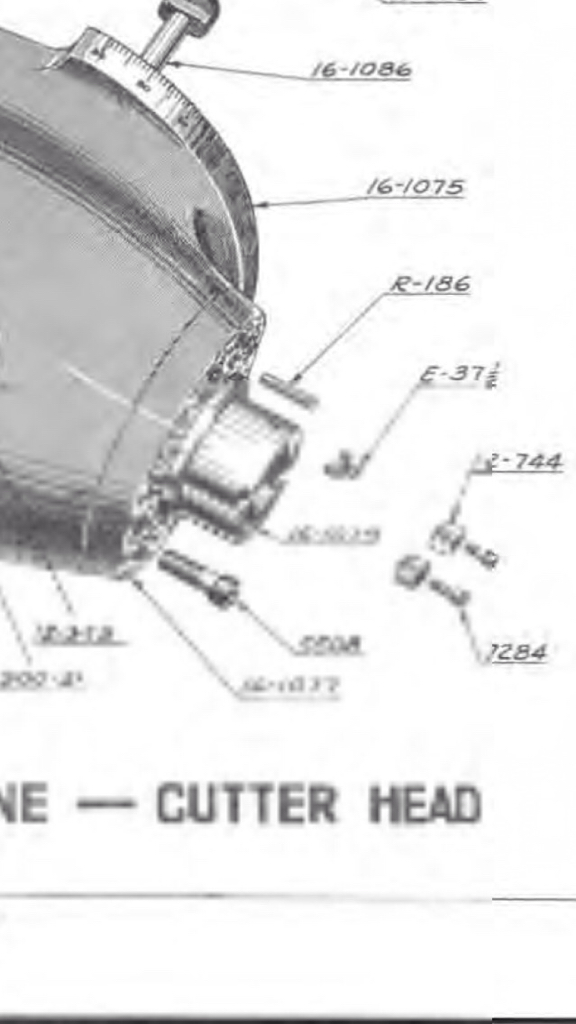

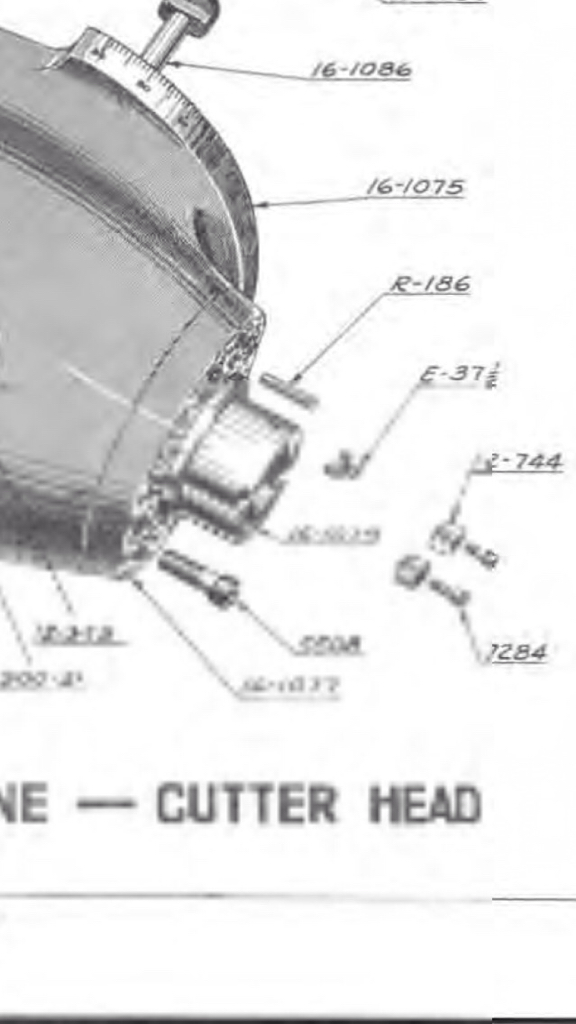

Does not show in parts drawing. Pictures low quality from my phone but help explain.

Thanks for your thoughts. More questions to follow.

Sent from my iPhone using Tapatalk

Does not show in parts drawing. Pictures low quality from my phone but help explain.

Thanks for your thoughts. More questions to follow.

Sent from my iPhone using Tapatalk