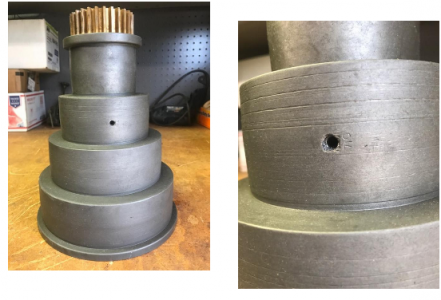

Really having a difficult time with an oiling set screw on a 14 1/2" x 60" SB lathe. It's located near the center of spindle step pulley. Tried heating, freezing, impact driver, and two kinds of penetrating oil ... finally had to drill it out

I managed to remove most of it with a drill that was a bit smaller than the set screw so I can still see some of the threads. I hope to re-tap it to the original size but there's several things I need to know:

1) It looks like a 1/4" standard thread (as opposed to fine) but I'm not sure?

2) What was the set screws length?

3) Was the set screw or hole tapered?

4) The set screw was slotted on one end but what was the opposite end like?

and 5) Did the hole and threads go all the way through to the spindle or was there some sort of seat (seal) that the set screw interacted with?

Just drilling all the way through and installing a larger set screw would be a simple fix but I'm afraid it might leak on the belt if there was in fact some sort of seat or seal originally.

The lathe didn't run when I got it but the re-build is almost finished and I've tried to keep everything as original as possible even though 14 1/2" parts are pretty scarce. So if anyone can help me figure out how to re-claim the original hole and set screw, I'd be very grateful.