- Joined

- Aug 26, 2014

- Messages

- 132

Resetting zero on the assumed depth of cut is a theoretical solution. In practice we cut until some solution is found, either with a thread mike, thread wires or a nut screwed on. There are too many pitfalls around theoretical depth

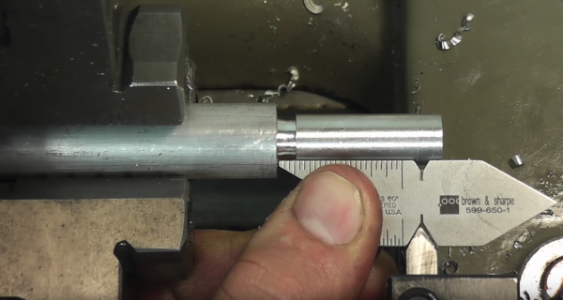

Oops, I missed the lower portion of the image, showing the buttress thread effect.

I was planning on checking progress before getting to full depth. I agree, "theoretical" limits are just a place to start.

It looks like your compound angle is set wrong. The angle should be 29.5º (more or less) to the cross slide feed. Some compound dials measure the angle between the spindle axis and the compound. If that is the case for your lathe, you should be setting the angle 60.5º.

I'm using an HLV-H, and I think you may be right. It looks like I set it on 30 when I needed "60".

Depending on how much depth of cut is remaining, you might be able to save it. I cannot tell by the pics how far you have already cut. You will lose maximum diameter while getting the flank angles correct. If that puts the threads under the major diameter, then you will have to start over. If you think you can save it, make sure you are moving toward a position where the current O.D. will get cut down as little as possible while getting the geometry correct.

I'm doing this at 125 RPM. Do you have a video recommendation?In addition to the compound angle - maybe the tool orientation with the work piece axis of rotation.

There are some really fine you tube how to videos in this regard. 4 tpi is a "fast" thread. Having a very low spindle speed would be a great help.

Some further explanation. If you ignore the compound and just advance the feed with the cross slide, you will cut both flanks of the thread equally. The cutting tool is a form tool and the shape of the of the thread mirrors the form.

On the other hand, if the compound is set at exactly 30º, the tool will travel along the previously cut surface and all cutting with the exception of a small amount at the tip of the tool will occur on the left flank. If the compound is set at an angle greater than 30º, the tool will not engage the previously cut portion of the right flank as it is advancing at a greater angle to the work. The cut at the right flank will create a small step or saw tooth. This step is visible in your photos.

The compound angle is set to slightly less than 30º to avoid any step caused by mis-setting the angle to more than 30º and to provide a slight shearing cut to dress the right f.lank. Although a smaller angle will do the same, cutting both flanks equally or close to equally has a tendency to cause chatter, especially on coarser threads.

I tried this before, with an Acme thread, and feeding directly in, but the machine just couldn't handle that much material removal. Even at .001 on diameter DOCs, feeding straight in was just too much for the machine. Chips would pack in there, and it would just stall.