- Joined

- Jan 3, 2024

- Messages

- 4

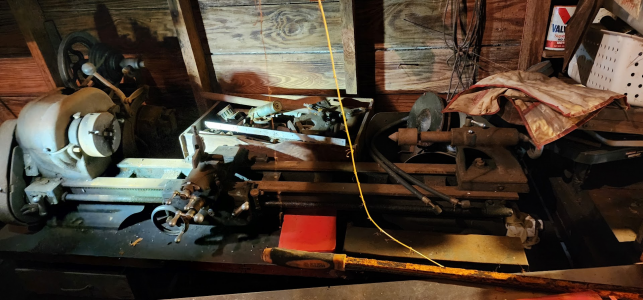

Just before Thanksgiving I picked up a TH54 from my neighbor, drug it from the back of a dark, dirt-floored shed, absolutely filthy. No broken teeth, ways are not badly worn, a fair amount of tools/attachments included. Loads of old small and large diameter brass bar stock in the bottom drawer to practice on. The top drawer is still in limbo, it's a pretty messy hoarder situation next door and it's dark so I'm trying to dig for additional attachments and tools from time to time.

Pulled the spindle, cross slide, compound, and apron, everything looks to be well cared for, even after sitting in less-than-ideal conditions for over three decades.

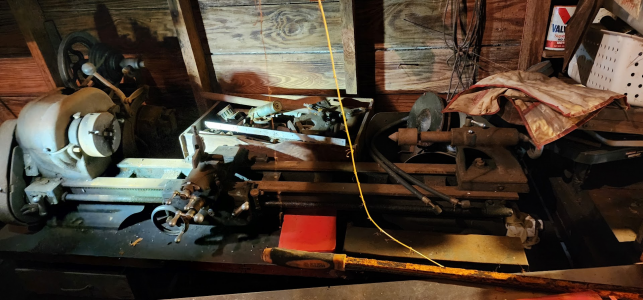

Some before and after, still needs some cleaning up but it's running without issue and your hands don't get dirty by touching it anymore so I consider that progress. Still ironing out how I want everything laid out in the garage but it's coming together.

Pulled the spindle, cross slide, compound, and apron, everything looks to be well cared for, even after sitting in less-than-ideal conditions for over three decades.

Some before and after, still needs some cleaning up but it's running without issue and your hands don't get dirty by touching it anymore so I consider that progress. Still ironing out how I want everything laid out in the garage but it's coming together.