-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

50,000 RPM Mill Spindle

- Thread starter JimDawson

- Start date

I had to mill some very fine slots in aluminum and had the same idea of fitting the Hf grinder to a bt40 holder. Did you try to use it for anything besides engraving or possibly measure the run out on the grinders spindle? I may have to look into doing this. Thanks

- Joined

- Feb 8, 2014

- Messages

- 11,176

I had to mill some very fine slots in aluminum and had the same idea of fitting the Hf grinder to a bt40 holder. Did you try to use it for anything besides engraving or possibly measure the run out on the grinders spindle? I may have to look into doing this. Thanks

I haven't had a chance to play with it since I ran the first engraving test. I haven't checked the run out yet, by eyeball it looked pretty good.

I have heard of others using this grinder for circuit board work, so it is probably up to some light milling.

For $24 (on sale) and a little time I would say it's worth checking out

- Joined

- May 7, 2014

- Messages

- 776

so simple I smacked my head! LOL .: 50,000 RPM Mill Spindle

Ken, LUV it! Duh- So simple and it's perfect. Awesome call! Going to HF!

- - - Updated - - -

Frigg'n AWESOME Stuff gang! Going to HF tomorrow to grab the pen holder grinder and see what else they have. Jim, D thanks for always posting Pics! Very kind of ya Sir. And Kens post on his holder is just too easy to say no too. I'm embarressed if I do not at least make that setup. If I cannot, the wife can chuck the machine out so I'll come to bed again most weekends. ;-)

- - - Updated - - -

I think this might be design to also put in a tension (spring) loaded setup as well?? Say 1/2" to 3/4" of V travel? I saw some neat tricks w/ that type of capability.

CG

Ken, LUV it! Duh- So simple and it's perfect. Awesome call! Going to HF!

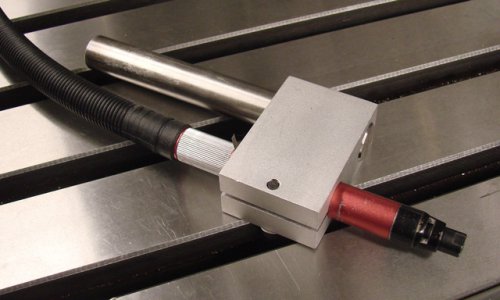

Just to throw in another approach with that kind if grinder...if you can lock your spindle.

Ken

- - - Updated - - -

Frigg'n AWESOME Stuff gang! Going to HF tomorrow to grab the pen holder grinder and see what else they have. Jim, D thanks for always posting Pics! Very kind of ya Sir. And Kens post on his holder is just too easy to say no too. I'm embarressed if I do not at least make that setup. If I cannot, the wife can chuck the machine out so I'll come to bed again most weekends. ;-)

- - - Updated - - -

I think this might be design to also put in a tension (spring) loaded setup as well?? Say 1/2" to 3/4" of V travel? I saw some neat tricks w/ that type of capability.

CG

Just to throw in another approach with that kind if grinder...if you can lock your spindle.

Ken

- Joined

- Feb 8, 2014

- Messages

- 11,176

I did a job today that gave me a chance to give the HF pencil grinder a real workout. I was starting to get a bit of chatter towards the end of the run, so I suspect the spindle bearings might be getting a bit loose. I don't think it was designed to run under a heavy load for 16 hours. The in-line air oiler doesn't seem to work, so I stopped to squirt a bit of oil in the line every so often. I will replace the regulator that I have on there now with a complete air service unit with filter and oiler.

I had to make 550 of these little guys out of 0.020, 260 brass. The endmill is a HHS, 2 flute, 10* taper, with a 0.005 tip. Because of the low power of the grinder, I found about 3.8 IPM was the best feed rate I could muster. My 5 HP air compressor got a pretty good workout also, it ran about 50% of the time, about a 2 minute on, 2 minute off cycle. I was running the grinder at about 70 PSI. Power cost for air for the run was about $4.00

The 10x24 brass sheets (2 req) were double-side carpet taped to pieces of 3/4 inch MDF. I used deck screws to screw that down to another piece of 3/4 inch MDF that was bolted to the T-slots with countersunk screws.

16 hours later, it's on the last column of parts.

I had a lot of time to work on cleaning up the shop while this was running. Still not done with the shop, maybe tomorrow.

To see the guts of this take a look here http://www.hobby-machinist.com/showthread.php?t=23186&p=205311&viewfull=1#post205311

I had to make 550 of these little guys out of 0.020, 260 brass. The endmill is a HHS, 2 flute, 10* taper, with a 0.005 tip. Because of the low power of the grinder, I found about 3.8 IPM was the best feed rate I could muster. My 5 HP air compressor got a pretty good workout also, it ran about 50% of the time, about a 2 minute on, 2 minute off cycle. I was running the grinder at about 70 PSI. Power cost for air for the run was about $4.00

The 10x24 brass sheets (2 req) were double-side carpet taped to pieces of 3/4 inch MDF. I used deck screws to screw that down to another piece of 3/4 inch MDF that was bolted to the T-slots with countersunk screws.

16 hours later, it's on the last column of parts.

I had a lot of time to work on cleaning up the shop while this was running. Still not done with the shop, maybe tomorrow.

To see the guts of this take a look here http://www.hobby-machinist.com/showthread.php?t=23186&p=205311&viewfull=1#post205311

That is awesome Jim. Really slick stuff there. And that is one tiny end mill.I did a job today that gave me a chance to give the HF pencil grinder a real workout. I was starting to get a bit of chatter towards the end of the run, so I suspect the spindle bearings might be getting a bit loose. I don't think it was designed to run under a heavy load for 16 hours. The in-line air oiler doesn't seem to work, so I stopped to squirt a bit of oil in the line every so often. I will replace the regulator that I have on there now with a complete air service unit with filter and oiler.

I had to make 550 of these little guys out of 0.020, 260 brass. The endmill is a HHS, 2 flute, 10* taper, with a 0.005 tip. Because of the low power of the grinder, I found about 3.8 IPM was the best feed rate I could muster. My 5 HP air compressor got a pretty good workout also, it ran about 50% of the time, about a 2 minute on, 2 minute off cycle. I was running the grinder at about 70 PSI. Power cost for air for the run was about $4.00

View attachment 82941

The 10x24 brass sheets (2 req) were double-side carpet taped to pieces of 3/4 inch MDF. I used deck screws to screw that down to another piece of 3/4 inch MDF that was bolted to the T-slots with countersunk screws.

View attachment 82942

16 hours later, it's on the last column of parts.

View attachment 82943

I had a lot of time to work on cleaning up the shop while this was running. Still not done with the shop, maybe tomorrow.

To see the guts of this take a look here http://www.hobby-machinist.com/showthread.php?t=23186&p=205311&viewfull=1#post205311

View attachment 82941 View attachment 82942 View attachment 82943

The slop in my old Millrite would snap that end mill in a New York second. But, I'm hoping that I can pull off a decent Pentograph engraver. Thats what I'm building right now. Bought the plans of the Pentograph from Joe Pie and am about 80% complete. And have my new die grinder like you have. So I'm hoping I can pull off some basic engraving. But, I know ( or think? ) before I even tried, that my mill has way too much slop to pull off using a end mill that small.

Very cool stuff Jim.