- Joined

- Nov 3, 2023

- Messages

- 37

I'm doing manual milling, found myself using a spreadsheet to calculate how many handwheel turns and subsequent ticks on the dial to move the cutter. That was a bit of a pain, so I set out to make a program to do that calculation. After about a week of fiddling, here 'tis:

https://github.com/butcherg/turnsticks/releases/tag/v0.1

This release is a Windows program, but the source code is there for anyone brave enough to try compiling it for something like Ubuntu Linux...

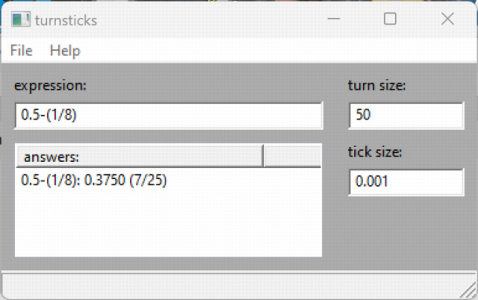

Here's a screenshot:

Basically, you enter a value or math expression in the expression box, press Enter, and the equation, numeric anser, and computed handwheel turns/ticks are posted in the answers box. If you enter another expression, the results are added to the box, so you can make a collection of measurements you're working with. The size boxes to the right are where you calibrate the tool to your handwheel; right now, it hard-code loads the Sherline numbers, but they can be changed once the program is running.

I've found the ability to enter a math equation to be a significant time-saver. The example in the screenshot is the width of a slot to be cut (0.5") minus the endmill diameter (1/8"), didn't have to spend time with the calculator to determine a single number to enter.

Anyway, am I the only one weird enough to find use for such a thing?

https://github.com/butcherg/turnsticks/releases/tag/v0.1

This release is a Windows program, but the source code is there for anyone brave enough to try compiling it for something like Ubuntu Linux...

Here's a screenshot:

Basically, you enter a value or math expression in the expression box, press Enter, and the equation, numeric anser, and computed handwheel turns/ticks are posted in the answers box. If you enter another expression, the results are added to the box, so you can make a collection of measurements you're working with. The size boxes to the right are where you calibrate the tool to your handwheel; right now, it hard-code loads the Sherline numbers, but they can be changed once the program is running.

I've found the ability to enter a math equation to be a significant time-saver. The example in the screenshot is the width of a slot to be cut (0.5") minus the endmill diameter (1/8"), didn't have to spend time with the calculator to determine a single number to enter.

Anyway, am I the only one weird enough to find use for such a thing?