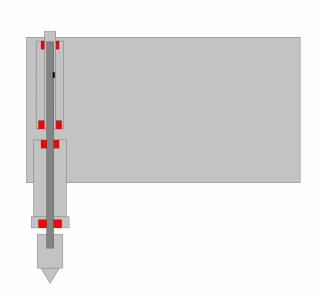

So i picked up my first "real" machine tool today. A vintage AEG drill press.

My initial research suggest its made in the 1980s, and weigh about 80kg.

It popped up in the norwegian version of craigslist and i got it for a crazy $30.

Not knowing anything about it other than it being "old and german" i had to have it.

After getting it home and somewhat clean, i think i made a very very good deal. If they put a Röhm Spiro chuck on it, i guess everything is pretty well made.

My plan is to clean it, change bearings and get a VFD and have it run on single phase. Any suggestions or tips here?

Here are some pictures from the add, and my initial disassembly and cleaning.

My initial research suggest its made in the 1980s, and weigh about 80kg.

It popped up in the norwegian version of craigslist and i got it for a crazy $30.

Not knowing anything about it other than it being "old and german" i had to have it.

After getting it home and somewhat clean, i think i made a very very good deal. If they put a Röhm Spiro chuck on it, i guess everything is pretty well made.

My plan is to clean it, change bearings and get a VFD and have it run on single phase. Any suggestions or tips here?

Here are some pictures from the add, and my initial disassembly and cleaning.