I have a bit of a noob question here. I am getting ready to machine a piece of flat bar. 3/4" x 5" x about 50" I need to machine 5 precise rectangular holes in it. So my game plan was to machine the 3 in the middle like normal with the turret centered. But my question is about the ends. I have a 48" table and wanted to machine it all without moving and resetting the part. So I was considering just rotating the turret toward the ends of the table to machine the outer holes. I was wondering though :

-Am I going to impart excessive slop from the gibs trying to machine this way or is this common practice that I have not seen yet?

-Should I just move the part over the table a few times to get it all?

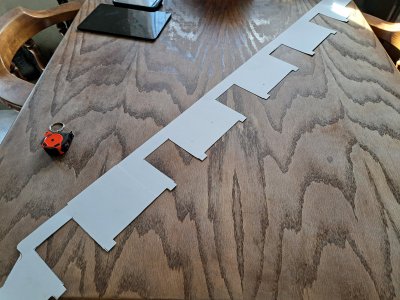

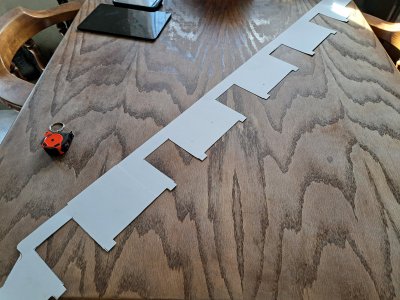

Attached is a paper outline of what I am trying to make.

Thanks for any info or opinions.

-Am I going to impart excessive slop from the gibs trying to machine this way or is this common practice that I have not seen yet?

-Should I just move the part over the table a few times to get it all?

Attached is a paper outline of what I am trying to make.

Thanks for any info or opinions.

Last edited: