- Joined

- Oct 5, 2010

- Messages

- 1,043

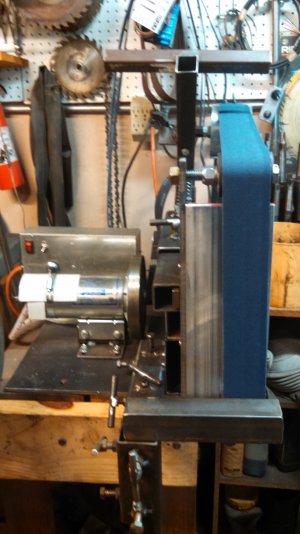

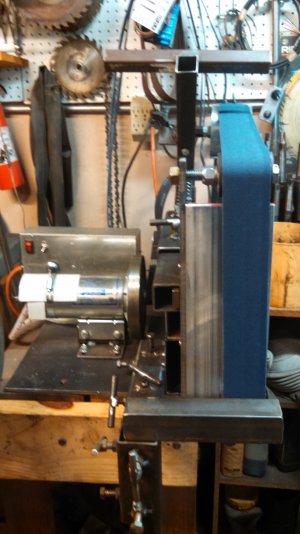

I started this about 2 months ago after salvaging a treadmill motor. The design is pretty much my own,

built almost completely form material from my scrap bin and a free treadmill. The build went pretty quickly. I got it finished and running and then burnt out the control board on assembly. (I tried to assemble it with the power on and smoked it good 8^( )

built almost completely form material from my scrap bin and a free treadmill. The build went pretty quickly. I got it finished and running and then burnt out the control board on assembly. (I tried to assemble it with the power on and smoked it good 8^( )

I got a new control board and finished it up today. This time I made sure that there was no power on. The motor is listed as 2,5hp and is variable from way too slow to way too fast. Seriously, it runs very well and I am happy with the final result. Sorry for the cluttered pictures, but I work in a cluttered shop.

Randy

built almost completely form material from my scrap bin and a free treadmill. The build went pretty quickly. I got it finished and running and then burnt out the control board on assembly. (I tried to assemble it with the power on and smoked it good 8^( )

built almost completely form material from my scrap bin and a free treadmill. The build went pretty quickly. I got it finished and running and then burnt out the control board on assembly. (I tried to assemble it with the power on and smoked it good 8^( )I got a new control board and finished it up today. This time I made sure that there was no power on. The motor is listed as 2,5hp and is variable from way too slow to way too fast. Seriously, it runs very well and I am happy with the final result. Sorry for the cluttered pictures, but I work in a cluttered shop.

Randy