Background Arbor Supports are serialized to match the mill they were born with.

Question Will they interchange? Can they be used on a different mill?

Answer No. But, Maybe...

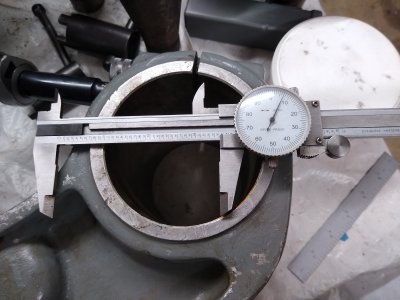

Rear Arbor Support 22L-1245 did not line up with the arbor bearing on my 24MLA. The bushing adjustment ring in the front of the support has been removed & the bushing pushed to the expanded position (the adjustment ring will not engage). It would take recutting the brass bushing to adapt it to your mill.

Stay tuned for trying to fit the Forward Arbor Support.

Question Will they interchange? Can they be used on a different mill?

Answer No. But, Maybe...

Rear Arbor Support 22L-1245 did not line up with the arbor bearing on my 24MLA. The bushing adjustment ring in the front of the support has been removed & the bushing pushed to the expanded position (the adjustment ring will not engage). It would take recutting the brass bushing to adapt it to your mill.

Stay tuned for trying to fit the Forward Arbor Support.