Hey guys, been reading trying to figure out the answer without posting however, I’m having a hard time figuring out something.

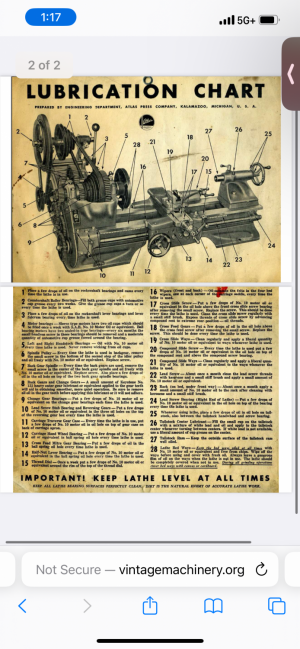

My machine was old and West Texas covered in dirt and Grease. disassembling the whole machine and cleaning it and putting it back together. I took the apron off the gears on the backside of the apron. Everyone keeps saying that they need 20 weight oil. However, every video I’m seeing shows Grease on these gears , I know there are oil ports on top for 20 weight none- detergent oil which I found also it seems non-detergent compressor oil is the same ,but when I looked up the original craftsman photo, it says to use 10 weight.

So do I put a light coat of grease on these gears on the backside of the apron as well as oil them overtime through the ports? If so, what kind of grease? And would I use the same grease on the gearbox and all the drives?

In the photo on 13 and 14, it says to use 10 weight everything else and everyone else I’ve seen I’ve said to use 20 weight.

My machine was old and West Texas covered in dirt and Grease. disassembling the whole machine and cleaning it and putting it back together. I took the apron off the gears on the backside of the apron. Everyone keeps saying that they need 20 weight oil. However, every video I’m seeing shows Grease on these gears , I know there are oil ports on top for 20 weight none- detergent oil which I found also it seems non-detergent compressor oil is the same ,but when I looked up the original craftsman photo, it says to use 10 weight.

So do I put a light coat of grease on these gears on the backside of the apron as well as oil them overtime through the ports? If so, what kind of grease? And would I use the same grease on the gearbox and all the drives?

In the photo on 13 and 14, it says to use 10 weight everything else and everyone else I’ve seen I’ve said to use 20 weight.

Attachments

Last edited by a moderator: