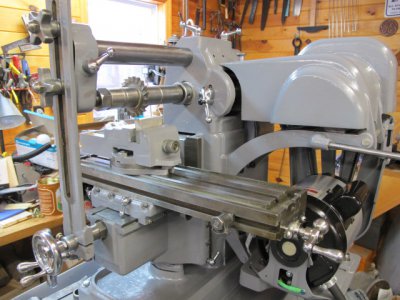

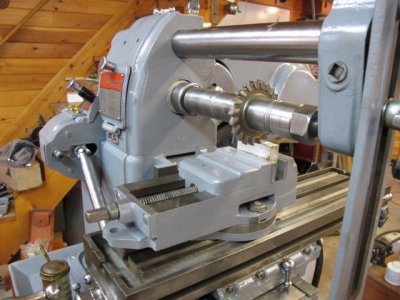

I just pickup a cast reproduction of the M1-61 Arbor Support off eBay. It's a rough casting that needs to be finished machined.

It looks pretty nice. A slight bit of porosity, but that was disclosed in the ad.

Thanks to wa5cab having uploaded the drawing, I have the dimensions. I'd like to reproduce it as close to the original as I can. If someone has an original that they could share some pictures from multiple sides, it would be much appreciated.

Atlas Horizontal Milling Machine, M1-61 Support Casting | eBay

Find many great new & used options and get the best deals for Atlas Horizontal Milling Machine, M1-61 Support Casting at the best online prices at eBay! Free shipping for many products!

www.ebay.com

It looks pretty nice. A slight bit of porosity, but that was disclosed in the ad.

Thanks to wa5cab having uploaded the drawing, I have the dimensions. I'd like to reproduce it as close to the original as I can. If someone has an original that they could share some pictures from multiple sides, it would be much appreciated.