- Joined

- Dec 3, 2017

- Messages

- 1,909

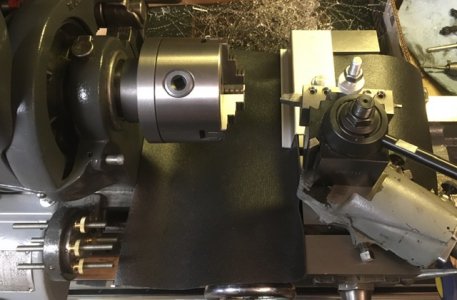

I hemmed and hawed around about paint. I figure if this goes the way the rest of it went I'll have it off and on half a dozen times before I get it right. So here's my first test fit. I had to take a lot more off than I saw in the bulletin. But maybe I just missed some details. I think I'm more fond of the looks of the change gear lathe than the qc version. But we will see at the end. The point is to not have to change gears after all..." looks" come second I suppose.

I can't seem to get a good mesh with the reverse selector. Either it's good in fwd but reverse is barely engaged, or vice versa. I'm thinking altering the curve of the index plate may help? It's like the holes need to be further apart. I flipped the spindle gear because the other side had better teeth, and that helped a little. But I'm not happy with it yet. I'll pick it up tomorrow and try again.

I can't seem to get a good mesh with the reverse selector. Either it's good in fwd but reverse is barely engaged, or vice versa. I'm thinking altering the curve of the index plate may help? It's like the holes need to be further apart. I flipped the spindle gear because the other side had better teeth, and that helped a little. But I'm not happy with it yet. I'll pick it up tomorrow and try again.