- Joined

- Jan 20, 2016

- Messages

- 173

I hauled home my latest auction treasure yesterday, a 1974 Rockwell / Delta 14" Metal/Wood Bandsaw (28-300). Lets just say she was rode hard and put away wet frequently. PO must not have been very mechanical, as see lots of things jerry rigged and or messed up after scraping away worst of the crud.

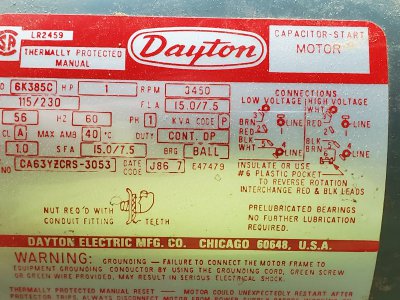

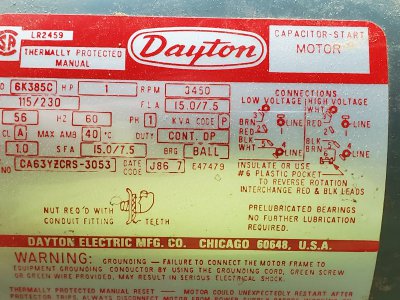

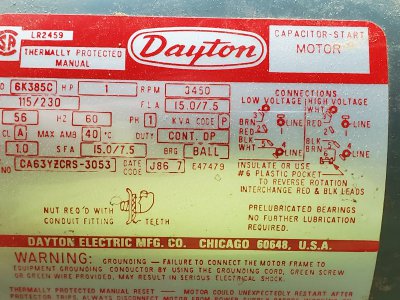

So first thing, try out the motor to see if it is even worth fixing this beast. Has this tag:

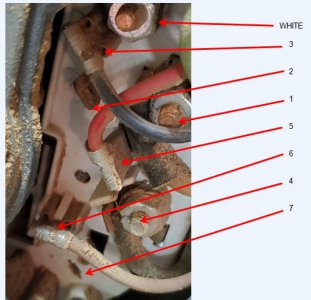

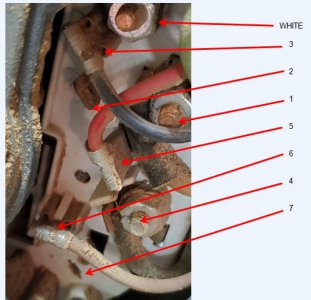

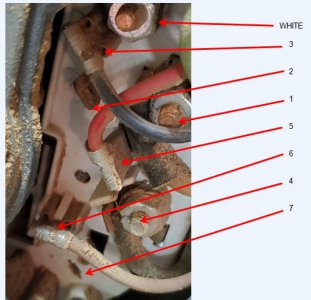

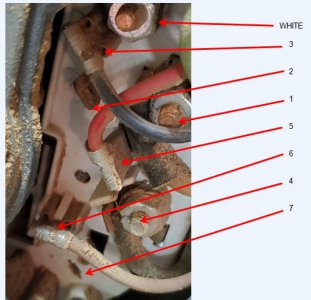

and photo that shows the wiring to be

a little hard to see, but black tape on white line @ 1, 2 empty, 7 missing. Three wire input (heavy), white, black and green; green to motor ground screw. So that looks like set up for high voltage (230), with red and black reversed (3 and 5).

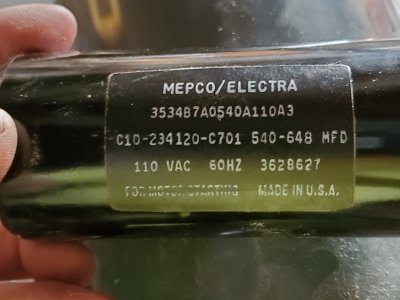

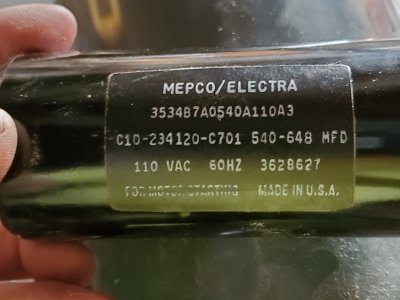

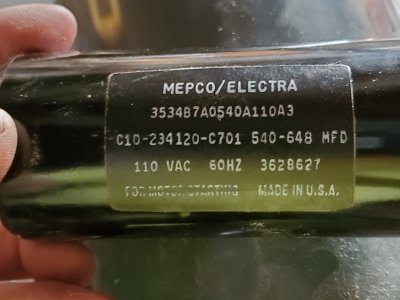

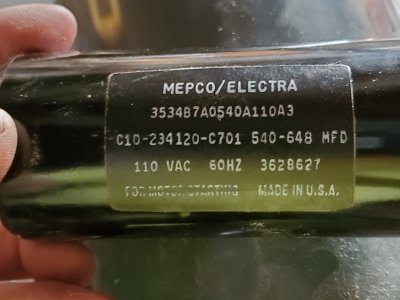

Hooked it up to 230 outlet with white wire to house red, and black wire to house black. Thought I might have to reverse them, but expected to turn one direction or other. Motor turned, but only about maybe 50 rpm. Not much of an electrical wizard, but pulled the cap out of the cover and saw this

Does this make sense, a 110 cap for a 230 motor wiring? Could the cap be why it won't run full speed (turns freely by hand)?

Or am I doing something else wrong?

Thanks for any help,

Ted

So first thing, try out the motor to see if it is even worth fixing this beast. Has this tag:

and photo that shows the wiring to be

a little hard to see, but black tape on white line @ 1, 2 empty, 7 missing. Three wire input (heavy), white, black and green; green to motor ground screw. So that looks like set up for high voltage (230), with red and black reversed (3 and 5).

Hooked it up to 230 outlet with white wire to house red, and black wire to house black. Thought I might have to reverse them, but expected to turn one direction or other. Motor turned, but only about maybe 50 rpm. Not much of an electrical wizard, but pulled the cap out of the cover and saw this

Does this make sense, a 110 cap for a 230 motor wiring? Could the cap be why it won't run full speed (turns freely by hand)?

Or am I doing something else wrong?

Thanks for any help,

Ted