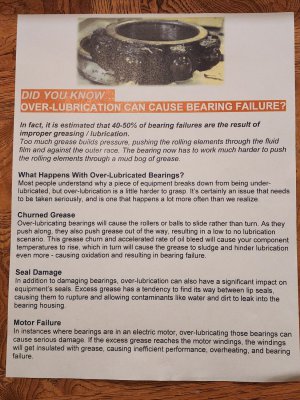

I was at a industrial supply store and asked them for a copy of this bulletin. No idea on which company put it together but I thought it may help us all. I keep reading abosome machines with what appears to be Grease Zirks when in fact they are for oil. And then I have run into the wrong lube recommend for my rebuild. Clausing stipulation on lube for the 8520 and 8530 spindeil bearing as 20 wt oil. No grease. But several people on this forum and other forums said grease, half full, quarter full or packed. So I guess the best info is go with what the original manufacturer recommends. Check this out.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bearing information

- Thread starter Oldseabee

- Start date

Over lubrication is one of the most common failure modes with bearings, much higher percentage of failures than under lubrication. Another aspect of that is using the incorrect viscosity, many places say just use an NLGI #2 grease, but that is the thickener consistency and not related to the oil in the grease that does the actual lubrication. You can get low to high viscosity greases and still be NGLI #2 for the thickener. One company I worked for had a customer that used the wrong grease with a high viscosity (recommended to them by a grease salesman) in a motor drive housing and did about $40,000 in damage when the shaft bent from the excessive heat.

I would always go with what the manufacturer recommends since the machine was designed for that and they should know what works. Spindle bearings should never be packed full unless there is extra room in the housing to let the excess out when it starts rotating. The exception to that is low speed spindles can be packed full since they rotate slow enough that churning doesn’t happen, but in most cases, a couple pumps of grease at regular intervals is more than enough.

My Burke Millrite has grease zerks for the way lubrication, but they are meant to be used with way oil. The previous owner used grease and I had to take it apart and clean it out before it would operate smoothly again. I was the reliability engineering manager for the last company I worked for and we had color coded grease zerks and grease guns to try and prevent the wrong type of grease to be used, even that didn’t always work…

I would always go with what the manufacturer recommends since the machine was designed for that and they should know what works. Spindle bearings should never be packed full unless there is extra room in the housing to let the excess out when it starts rotating. The exception to that is low speed spindles can be packed full since they rotate slow enough that churning doesn’t happen, but in most cases, a couple pumps of grease at regular intervals is more than enough.

My Burke Millrite has grease zerks for the way lubrication, but they are meant to be used with way oil. The previous owner used grease and I had to take it apart and clean it out before it would operate smoothly again. I was the reliability engineering manager for the last company I worked for and we had color coded grease zerks and grease guns to try and prevent the wrong type of grease to be used, even that didn’t always work…

- Joined

- Mar 21, 2018

- Messages

- 1,606

The problem with trying to make things idiot proof is that the world keeps making better idiots.... we had color coded grease zerks and grease guns to try and prevent the wrong type of grease to be used, even that didn’t always work…

Isn't that the truth! I still shake my head at the things I've seen during my career.The problem with trying to make things idiot proof is that the world keeps making better idiots.

- Joined

- Dec 14, 2018

- Messages

- 629

We had too constantly! You wouldn't believe the motors/ machines we dismantled that were filled with grease overflow!You can't fix stupid, but you can sure charge for it.

- Joined

- Nov 17, 2017

- Messages

- 1,525

Over in the world of guns::

If it slides:: grease it

If it rotates:: oil it.

If it slides:: grease it

If it rotates:: oil it.