- Joined

- Oct 29, 2012

- Messages

- 1,328

I got this Prusa printer over a decade ago and it was cutting edge stuff back then, but not so much now. I used it heavily for a couple of months and then it was forgotten. I pulled it back out a couple of years ago during a covid-vacation and printed a couple of widgets, then threw the sheet back over it.

Now I need it to make things for me. Lots of things. It isn't impressing me.

Part of the problem, I'm sure, is the 12 y/o yellowed/hardened ABS filament I'm using. It does work, but the filament is so stiff the printer has trouble drawing it in, and keeps slipping in drive rollers. I ordered some new filament (wasn't easy to find 3mm filament, everything is 1.75mm now) and will give that a shot, but there is another problem.

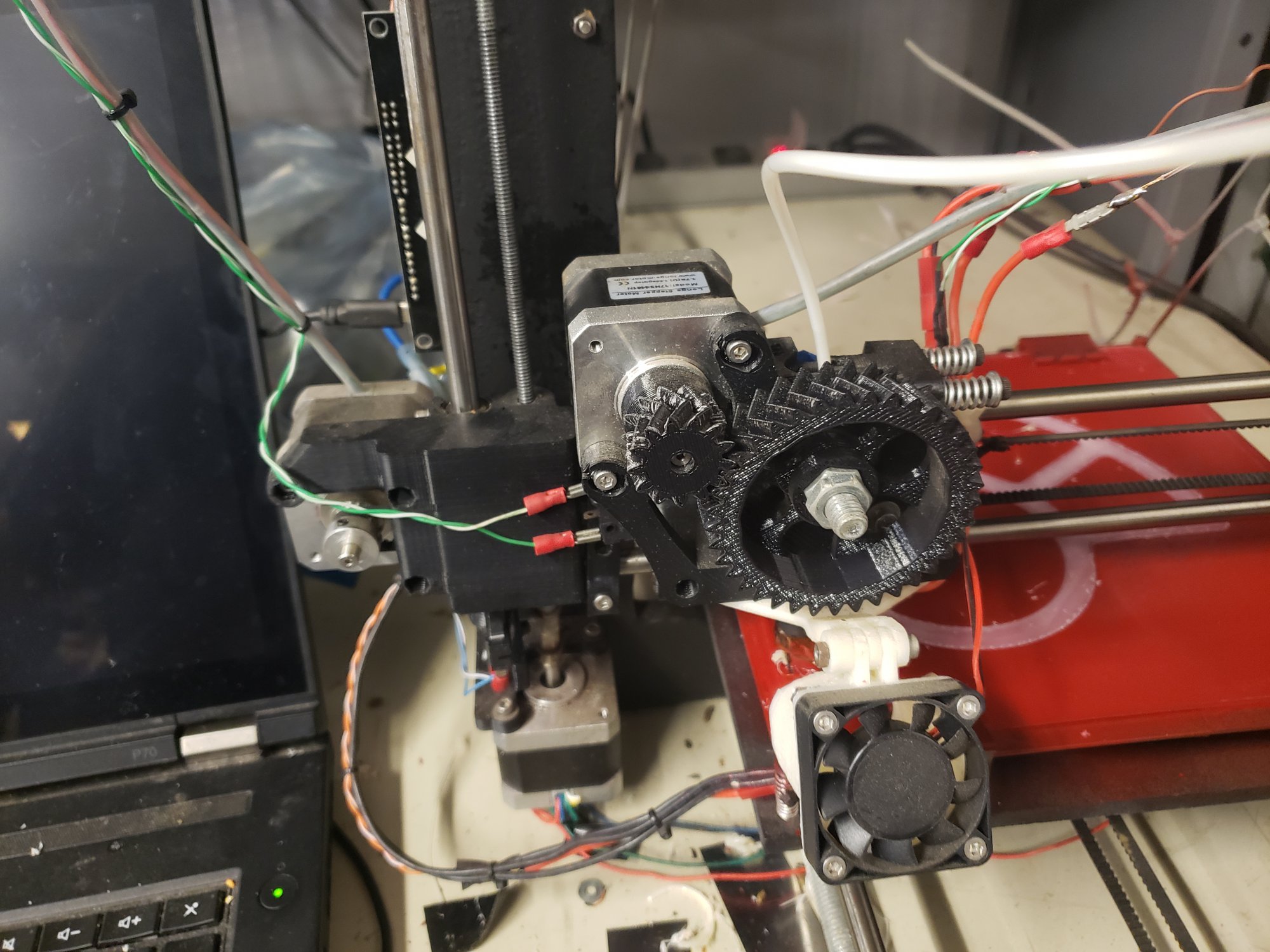

The gear on my extruder stepper was slipping on the shaft so I tightened the set screw until it stopped slipping, then I noticed a crack in the gear. I could print another (assuming it holds up that long) but should I? Surely there are better extruder now? I looked on the internet and the options are overwhelming. I'm looking for something that is a bolt-on replacement. I don't see anything that spells out what I need. There are upgrade guides but none (that I found) that make the entire generational gap from my old dinosaur to the hot new extruder.

For reference, this is the extruder I have currently:

The printer is a Prusa I3. Mendel? Rev0? I don't know, I remember enough to know that's only half the information but I don't remember what the other information was.

Now I need it to make things for me. Lots of things. It isn't impressing me.

Part of the problem, I'm sure, is the 12 y/o yellowed/hardened ABS filament I'm using. It does work, but the filament is so stiff the printer has trouble drawing it in, and keeps slipping in drive rollers. I ordered some new filament (wasn't easy to find 3mm filament, everything is 1.75mm now) and will give that a shot, but there is another problem.

The gear on my extruder stepper was slipping on the shaft so I tightened the set screw until it stopped slipping, then I noticed a crack in the gear. I could print another (assuming it holds up that long) but should I? Surely there are better extruder now? I looked on the internet and the options are overwhelming. I'm looking for something that is a bolt-on replacement. I don't see anything that spells out what I need. There are upgrade guides but none (that I found) that make the entire generational gap from my old dinosaur to the hot new extruder.

For reference, this is the extruder I have currently:

The printer is a Prusa I3. Mendel? Rev0? I don't know, I remember enough to know that's only half the information but I don't remember what the other information was.