- Joined

- Mar 12, 2014

- Messages

- 1,531

Well the other half of my order from Matt showed up yesterday. There was some slight delay due to the crate being lost in Fontana, CA but after Matt on the phone with them they were able to locate it and got it here in one day, amazing. Big shout out to Matt once more, his customer service is hands down second to none.

I did quite a bit of research for a replacement vertical bandsaw prior to calling Matt. I had looked locally for an older DoAll or equivelant, but again I live in a machinery desert and nothing around here even close. That or people just aren't parting with them.

I had my eye on a Jet that was to the high side of my budget but appeared to be pretty close to what I was looking for, I wanted a larger industrial grade machine with a minimum of 14" throat. My last one was a 14" and worked well but a little too light duty for me.

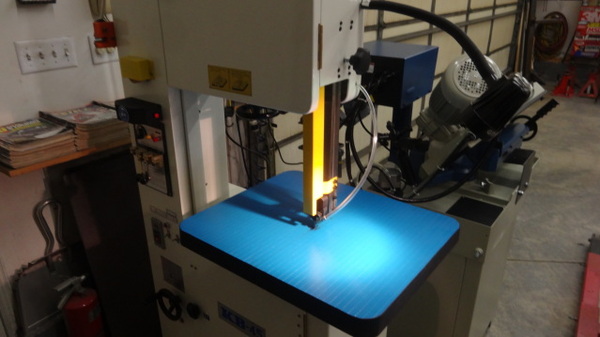

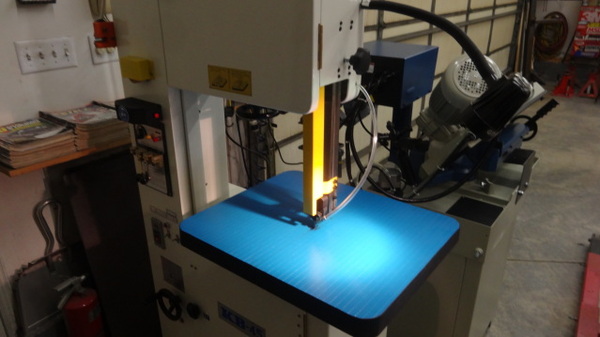

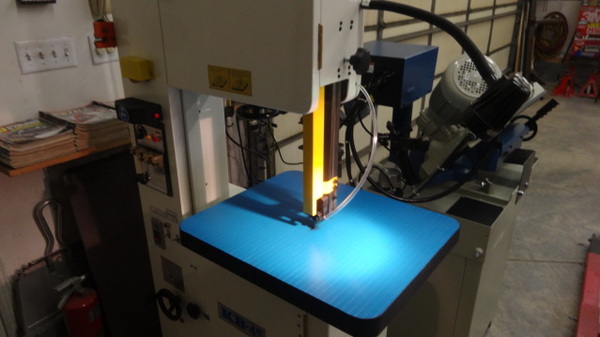

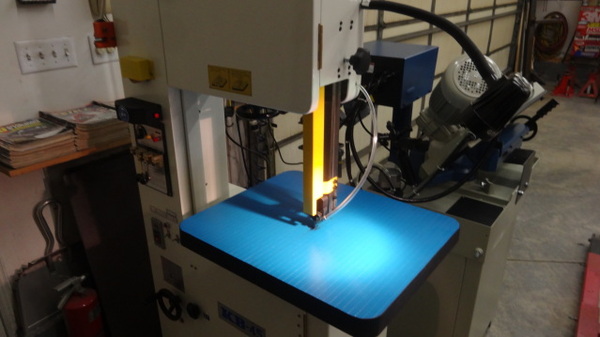

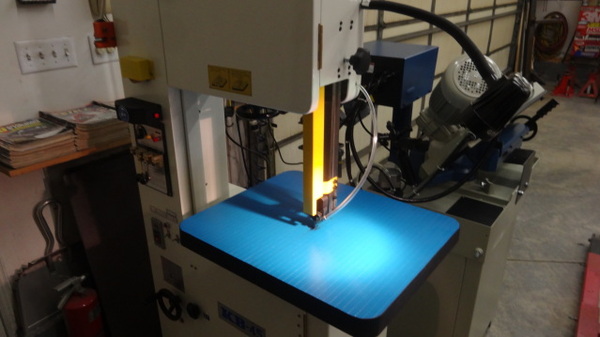

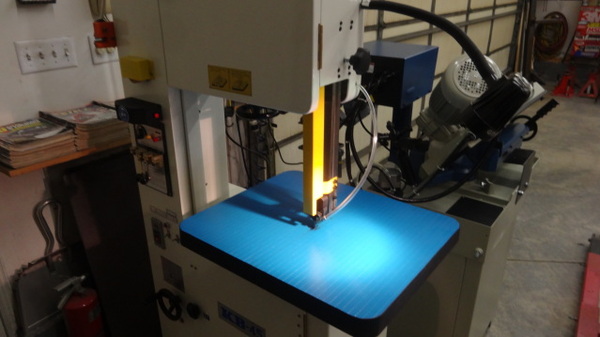

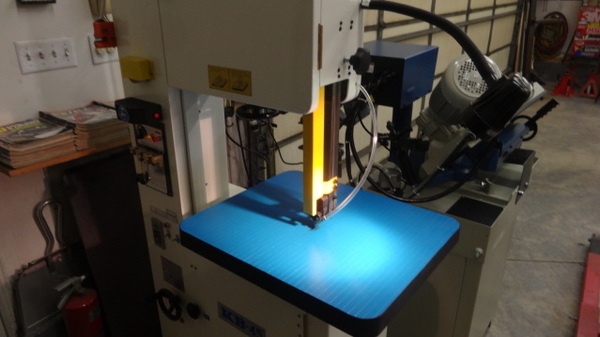

After calling Matt and inquiring about the Jet, he convinced me that he had a better option available. This KB-45 has an 18" throat and weighs around 800 pounds. It is a beast of a machine but very nicely equipped. It also comes with a built in blade welder, cutter, grinder and annealing setup on the side as well as a nice quality light.

My Birmingham KB-45 as it sat in my shop crated.

Uncrated but still on pallet.

Set in place and leveled up.

Plug wired and powered up. Light works.

Two new bandsaws placed next to each other.

After running it a little and checking it over carefully, my first impression is this is a nice high quality bandsaw. I will report back after getting some time on the machine. I will also do a video review as this machine is unbelievably quiet and smooth, something that cannot be conveyed over a forum.

Big thanks to Matt @ QMT. If anyone is considering stepping up to a nice vertical bandsaw give Matt a call or shoot him an email as he sells more than just lathes and mills.

Mike.

I did quite a bit of research for a replacement vertical bandsaw prior to calling Matt. I had looked locally for an older DoAll or equivelant, but again I live in a machinery desert and nothing around here even close. That or people just aren't parting with them.

I had my eye on a Jet that was to the high side of my budget but appeared to be pretty close to what I was looking for, I wanted a larger industrial grade machine with a minimum of 14" throat. My last one was a 14" and worked well but a little too light duty for me.

After calling Matt and inquiring about the Jet, he convinced me that he had a better option available. This KB-45 has an 18" throat and weighs around 800 pounds. It is a beast of a machine but very nicely equipped. It also comes with a built in blade welder, cutter, grinder and annealing setup on the side as well as a nice quality light.

My Birmingham KB-45 as it sat in my shop crated.

Uncrated but still on pallet.

Set in place and leveled up.

Plug wired and powered up. Light works.

Two new bandsaws placed next to each other.

After running it a little and checking it over carefully, my first impression is this is a nice high quality bandsaw. I will report back after getting some time on the machine. I will also do a video review as this machine is unbelievably quiet and smooth, something that cannot be conveyed over a forum.

Big thanks to Matt @ QMT. If anyone is considering stepping up to a nice vertical bandsaw give Matt a call or shoot him an email as he sells more than just lathes and mills.

Mike.