-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boring with an Atlas Milling Machine

- Thread starter JPMacG

- Start date

- Joined

- Dec 25, 2011

- Messages

- 10,511

For end mills, the most economical way (both in dollars and in real estate) is to hold them in collets of some sort. I'm not sure what Webster's would have to say on the matter, but when I think of arbors, I usually think of ones like are used for drill chucks, which are male to male. Atlas did make a face mill holder that was similar to what JPMacG came up with for mounting the boring head. We have the factory drawing for it.

- Joined

- Mar 22, 2014

- Messages

- 847

I have not tried it yet. I have two projects in mind that will need to have holes bored on the mill, but they are on the back burner for now. One is an arbor support bar for the mill itself, and the other is weight relief holes for aluminum angle wheel chocks for an airplane.

- Joined

- Nov 29, 2017

- Messages

- 530

For anyone considering a line boring bar type set up, check this link for a pic of a tool for setting the bit length.

Between Centres Boring Bars - hemingwaykits.com

Unique projects for the small workshop owner. Please browse our Toolroom and Engine Bay for our latest project kits.

www.hemingwaykits.com

- Joined

- Jan 2, 2014

- Messages

- 8,852

I made an adapter so that it could mount directly on the threads of the spindle, with part of the spindle nested within the head. This saves maybe two inches compared to mounting it using the Morse taper. I'll see how it works out.

Excellent and very compact solution!

Very nice.

-brino

- Joined

- Mar 22, 2014

- Messages

- 847

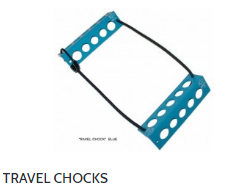

LOL... yes. My friend has a Cessna 150. He wants some lightweight chocks that he can carry with him when he goes for his "$100 cup of coffee". It is just two pieces of 1-1/2" aluminum angle with some weight relief, one set for each main wheel. Every ounce counts in a 150. To purchase them from an online aviation supplier would be around $40 for each wheel so I told him I would buy some angle stock and bore some holes.Wheel chocks for an airplane? Do TELL!!!! LOL..

- Joined

- Nov 2, 2013

- Messages

- 960

Neat project. You're a good man Charlie Brown! LOL..LOL... yes. My friend has a Cessna 150. He wants some lightweight chocks that he can carry with him when he goes for his "$100 cup of coffee". It is just two pieces of 1-1/2" aluminum angle with some weight relief, one set for each main wheel. Every ounce counts in a 150. To purchase them from an online aviation supplier would be around $40 for each wheel so I told him I would buy some angle stock and bore some holes.

View attachment 301099