- Joined

- Oct 12, 2023

- Messages

- 40

Hello,

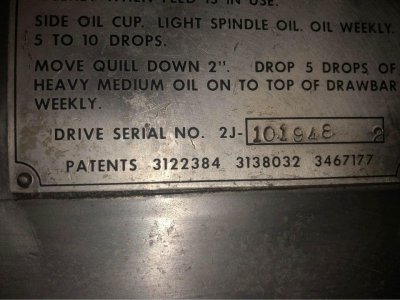

I have been researching knee mills for a little while. I currently have the PM-25, and just want something significantly larger. I came across this Bridgeport on Marketplace and wanted to ask for some opinions/advice on whether this is a great deal. I've already sent him a few preliminary questions, but wanted your input.

I know it will need some restoration and it doesn't come with a DRO, is there anything else that jumps out at anyone as a red flag? Or, do you have any important questions I should ask him?

1. I asked about the phase converter he mentions in the ad.

2. I asked about anything inoperable or in need of repair.

3. I asked about how often he has used it, and performed maintenance on it.

Any input would be appreciated. These are the photos from the ad. I can always request more.

Tony

I have been researching knee mills for a little while. I currently have the PM-25, and just want something significantly larger. I came across this Bridgeport on Marketplace and wanted to ask for some opinions/advice on whether this is a great deal. I've already sent him a few preliminary questions, but wanted your input.

I know it will need some restoration and it doesn't come with a DRO, is there anything else that jumps out at anyone as a red flag? Or, do you have any important questions I should ask him?

1. I asked about the phase converter he mentions in the ad.

2. I asked about anything inoperable or in need of repair.

3. I asked about how often he has used it, and performed maintenance on it.

Any input would be appreciated. These are the photos from the ad. I can always request more.

Tony