- Joined

- Apr 21, 2013

- Messages

- 208

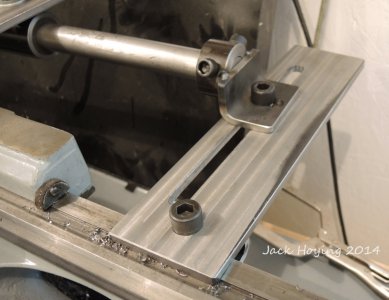

I finished the basic construction of a taper attachment on my 5914 lathe today. I still have some cleanup and painting to do on it, but it's mechanically finished. I used a 26" x 1" rod that I had on hand, along with some bronze bushing for the slide. The rest is pretty basic construction. I tried it out on a piece of metal that I had and the finish is very nice and smooth.

The brackets are 3/8" x 3" metal. There aren't any critical measurements here, so if you make one, just go with the materials you have on hand.

Like all taper attachments, the main work involves setting up the arm to cut an accurate taper, so that will take some experimenting with. I have to make a Morse 4 1/4 taper for my headstock, which will be my first real project on it.

A few more photos are on my website at http://www.pbase.com/jmhoying/taper

[video=youtube_share;N8JbfrUDDOY]http://youtu.be/N8JbfrUDDOY[/video]

A short video of it in action, making wire, instead of chips.

Jack

Fort Loramie, Ohio

The brackets are 3/8" x 3" metal. There aren't any critical measurements here, so if you make one, just go with the materials you have on hand.

Like all taper attachments, the main work involves setting up the arm to cut an accurate taper, so that will take some experimenting with. I have to make a Morse 4 1/4 taper for my headstock, which will be my first real project on it.

A few more photos are on my website at http://www.pbase.com/jmhoying/taper

[video=youtube_share;N8JbfrUDDOY]http://youtu.be/N8JbfrUDDOY[/video]

A short video of it in action, making wire, instead of chips.

Jack

Fort Loramie, Ohio