I bought this machine last week for $300 from a guy local in singapore and paid $90 for a truck rental to move it.

I'm starting this thread to document my restoration, scraping, CNC and ball screw upgrade as well as to dimension every single part in CAD.

Previously I've done some turning on the small 210mm lathe before so this would be a nice upgrade in rigidity and size for me. It took me a couple of years before I found this reasonably priced lathe.

I'm planning to hand scrape every sliding surface, maybe not check for alignment as thats too much work and upgrade the crossfeed T13 13mm leadscrew to a 1204 ball screw. And maybe add in stepper motor for cnc control.

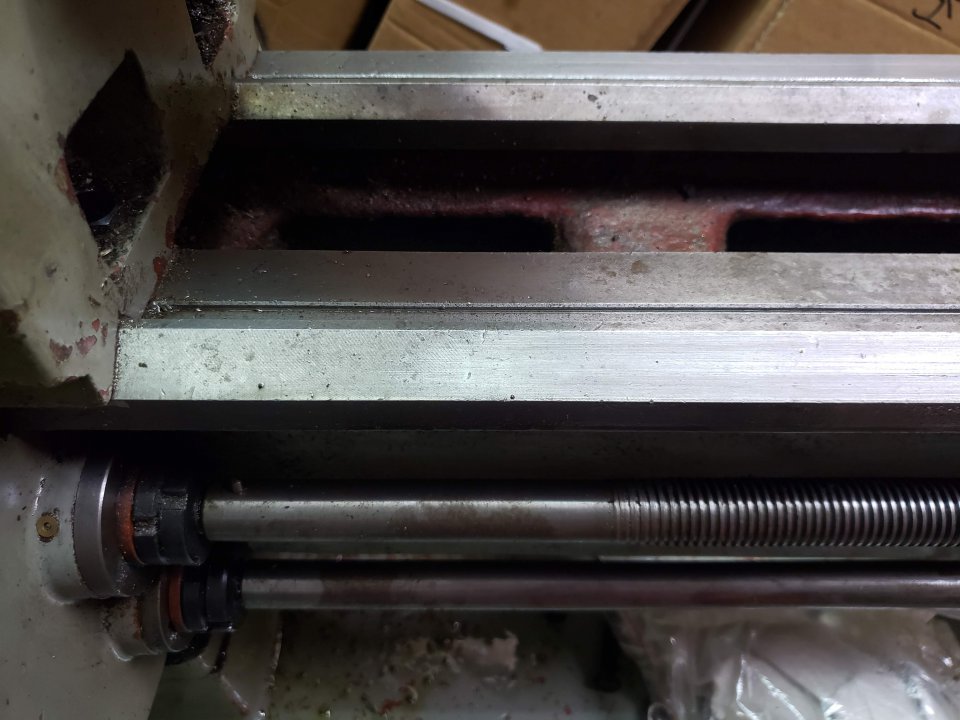

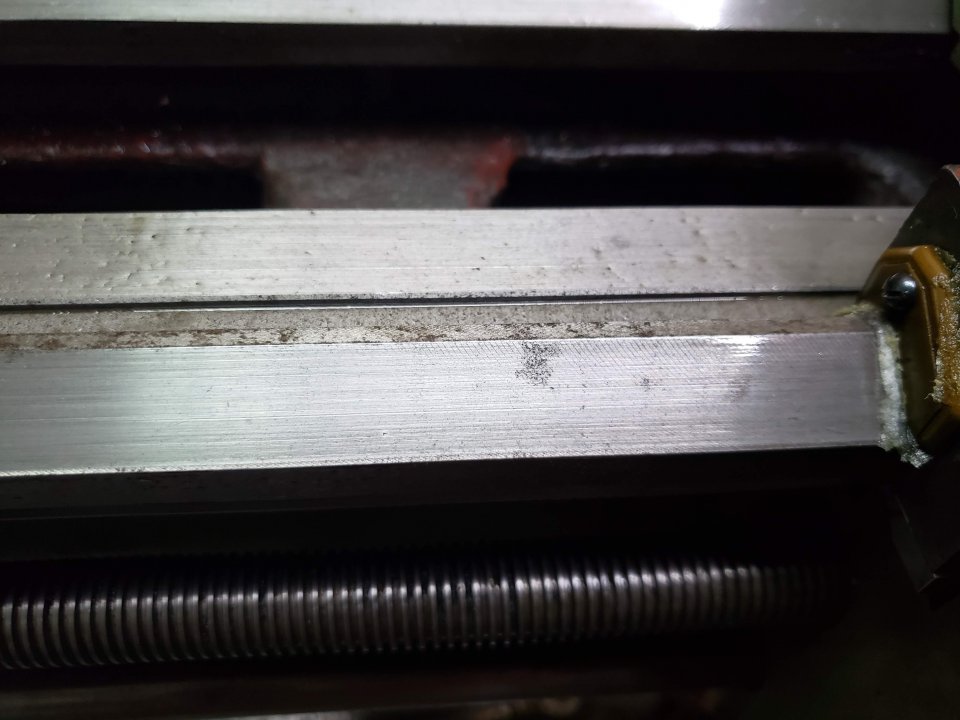

The lathe appears to be in reasonably good shape for its age, mfg 1975 in shanghai 11th machine works and its got barely any wear near the end of the ways, but heavy wear and scoring near the middle. I haven't measured the backlash or runout on the lathe yet as the dial indicator stand is in the mail, but I have taken the saddle and tail stock out to clean out the dirt and oil. I might try to apply turcity or use 0.03mm thick teflon sheet on the ways to help it slide better as all of the original scraping marks on the crossslide and compound has been worn away.

Another thing on my to do list is to add a central 1 shot lubrication system for the ways, as there are no oil ports or grooves in the cross slide and compound dovetail at all.

It came with some basic hss and brazed carbide cutting tools, a seized up knurling tool, some spare gears and a bigger 4 jaw chuck.

Some specs:

One Piece Cast chip pan

Spindle bushings + 2 thrust bearinbgs instead of tapered roller bearings

6 Speed gearbox

Quick change gears for both metric and inch threads

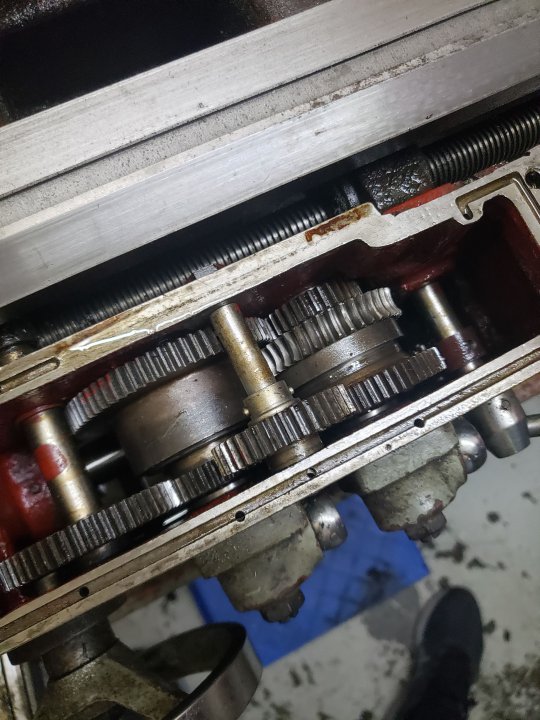

Automatic cross feed and saddle movement

300kg weight

New lathe!

Sticker

Bed ways

Some heavy scoring

End of the bed ways looks great, you can still see the factory milling marks

half worn milling marks

Compound

Hand for scale

Cross slide ways

Saddle gearbox with autofeed

I'm starting this thread to document my restoration, scraping, CNC and ball screw upgrade as well as to dimension every single part in CAD.

Previously I've done some turning on the small 210mm lathe before so this would be a nice upgrade in rigidity and size for me. It took me a couple of years before I found this reasonably priced lathe.

I'm planning to hand scrape every sliding surface, maybe not check for alignment as thats too much work and upgrade the crossfeed T13 13mm leadscrew to a 1204 ball screw. And maybe add in stepper motor for cnc control.

The lathe appears to be in reasonably good shape for its age, mfg 1975 in shanghai 11th machine works and its got barely any wear near the end of the ways, but heavy wear and scoring near the middle. I haven't measured the backlash or runout on the lathe yet as the dial indicator stand is in the mail, but I have taken the saddle and tail stock out to clean out the dirt and oil. I might try to apply turcity or use 0.03mm thick teflon sheet on the ways to help it slide better as all of the original scraping marks on the crossslide and compound has been worn away.

Another thing on my to do list is to add a central 1 shot lubrication system for the ways, as there are no oil ports or grooves in the cross slide and compound dovetail at all.

It came with some basic hss and brazed carbide cutting tools, a seized up knurling tool, some spare gears and a bigger 4 jaw chuck.

Some specs:

One Piece Cast chip pan

Spindle bushings + 2 thrust bearinbgs instead of tapered roller bearings

6 Speed gearbox

Quick change gears for both metric and inch threads

Automatic cross feed and saddle movement

300kg weight

New lathe!

Sticker

Bed ways

Some heavy scoring

End of the bed ways looks great, you can still see the factory milling marks

half worn milling marks

Compound

Hand for scale

Cross slide ways

Saddle gearbox with autofeed