- Joined

- Sep 28, 2013

- Messages

- 4,325

I have another project that needs an accurate bore depth but no way of measuring that on my lathe without stopping and using my digital caliper. I do have a set of iGaging scales to go on the lathe, but this seemed quicker. I also wanted to put to use the most awesome metric Mitutoyo micrometer head that Middle.Road graciously swapped for my slight less awesome and lengthy SAE Starrett one

took fewer pictures than I thought, oh well

making the bed step in one of the holders

lots of lovely long chips - really loving my variable speed drill press mod, works so much better than before. This was at 1600-1800rpm (1/4in em) vs. the 800rpm max that I could use before, without stepping up to 3000rpm.

carriage stop

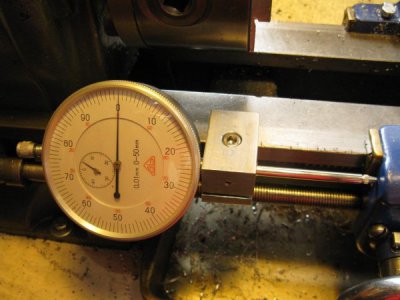

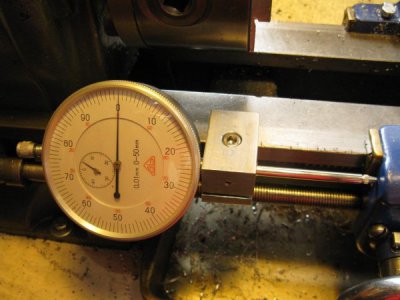

utterly crazy resolution, although I'll have to get used to reading it upside down

0-50mm dial indicator for the near sighted and legally blind. It's Chinese, from Beijing Tool Works, but it only cost $10 and it seems to work very nicely. And it's metric!

I was thinking it might be handy to incorporate a screw stop in the DI holder, but that'll have to wait.

pleased as punch with the holders and even more so with my "mill". These were the first projects I've done on it since adding the treadmill motor and boy is it awesome.

took fewer pictures than I thought, oh well

making the bed step in one of the holders

lots of lovely long chips - really loving my variable speed drill press mod, works so much better than before. This was at 1600-1800rpm (1/4in em) vs. the 800rpm max that I could use before, without stepping up to 3000rpm.

carriage stop

utterly crazy resolution, although I'll have to get used to reading it upside down

0-50mm dial indicator for the near sighted and legally blind. It's Chinese, from Beijing Tool Works, but it only cost $10 and it seems to work very nicely. And it's metric!

I was thinking it might be handy to incorporate a screw stop in the DI holder, but that'll have to wait.

pleased as punch with the holders and even more so with my "mill". These were the first projects I've done on it since adding the treadmill motor and boy is it awesome.

I use a DI on my lathe all the time.

I use a DI on my lathe all the time.