Perceptive question by the original poster and Welcome to this forum! I have a Tormach 1100 and a probe. When I bought the mill (used), the original owner used a Haimer 3D taster, but also had a mechanical edge finder and a touch-off LED one. I've used the Haimer, but tend to go to the probe. I've never used the mechanical edge finder or the LED one.

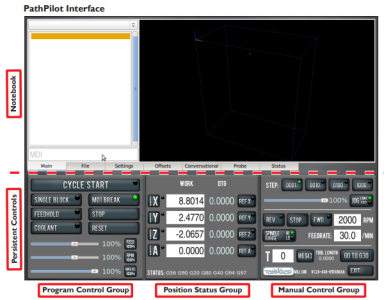

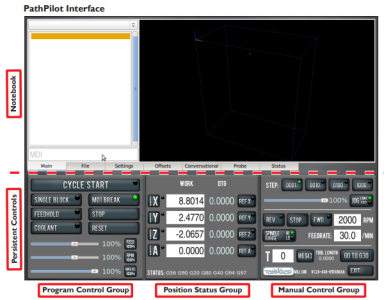

My Tormach runs PathPilot software which has routines built in for using the probe. Here's the MAIN screen (screen shots taken from Tormach's manual):

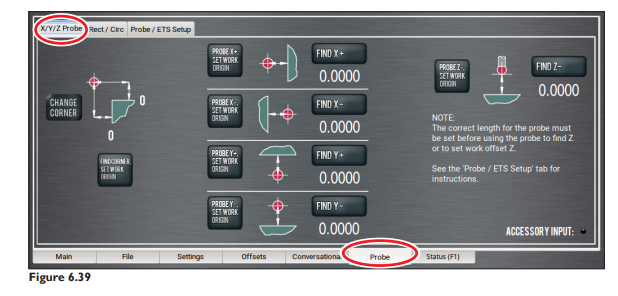

There are tabs like in Excel around the middle of the screen vertically; those jump to various subscreens like file handling, machine/accessory settings, tool offsets, conversational canned routines, probe and system status. The probe tab is below:

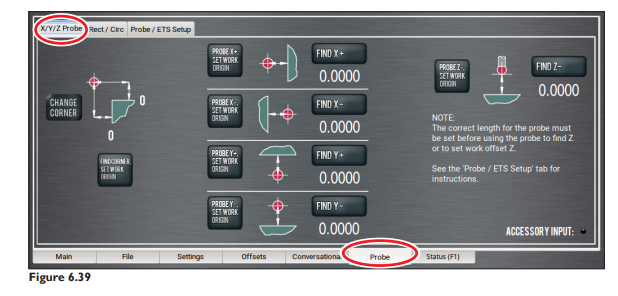

The X/Y/Z tab will probe a corner, edge or surface under machine control. In other words, manually position the probe tip off the corner by about 1/2", hit the button, and PathPilot works its magic.

In the bottom RH corner there's an ACCESSORY INPUT indicator. I ALWAYS flip the tip of my probe before running a routine just to make sure it's working correctly. A green dot lights up when the probe is activated. PathPilot runs the appropriate table axis/column at something like 20 inches per minute until the probe triggers, then backs off a bit, and repeats at 5 ipm, and Zero's the appropriate axis.

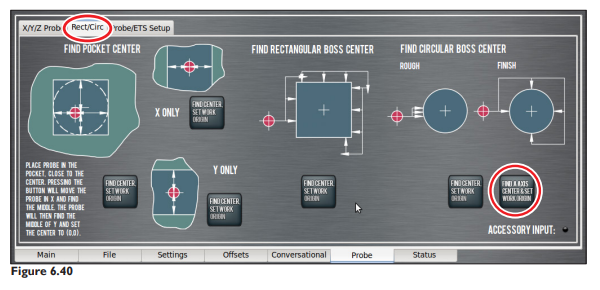

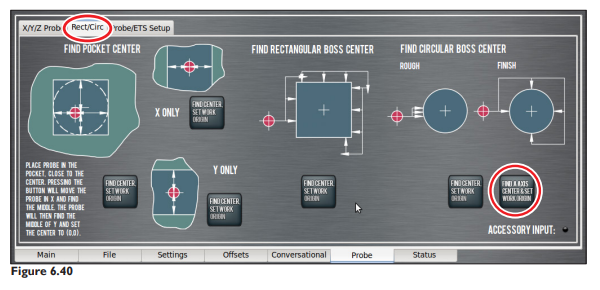

There's also a Rect/Circ tab for finding the center of a pocket in X, Y or both. Same for rectangular or circular bosses. There's also a routine if you're using a 4th axis that finds the center of the A-axis. All of this at the touch of a button.

It's the software driving the probe that makes it convenient and fast. If you don't have software driving the probe, you essentially have a touch-off light that works in 3-axes. The PathPilot software also has a probe set up routine to measure the diameter of the probe's tip; it uses that offset so you don't have to do the math like with a mechanical edge finder. Again, if you are using a probe without software, you'll jog until you see the light and have to manually input the tip radius for the proper offset.

Bruce