All the youtubes show the smaller chucks coming apart easily after a plate is removed, but I have not found any instructions on disassembling a 6" scroll chuck. This one is a 2004 with only .001" runout ! The condition of the lathe is good, but the chuck looks like it has never been opened and cleaned. After some head scratching I now ask for help from anyone who knows the secret. The only nomenclature on the chuck is a sticker, "Hua Pai."

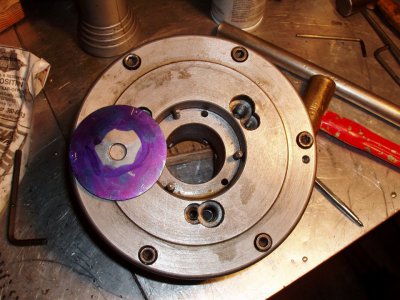

The picture attached shows the back side. I see what may be a parting line inside the bore so I made the washer shown and tried tapping-nothing. Last guess was that perhaps the halves were held together by a spanner nut. Tapping produced no movement. I have not tried a press because "it ain't broke..." Any help greatly appreciated.

The picture attached shows the back side. I see what may be a parting line inside the bore so I made the washer shown and tried tapping-nothing. Last guess was that perhaps the halves were held together by a spanner nut. Tapping produced no movement. I have not tried a press because "it ain't broke..." Any help greatly appreciated.