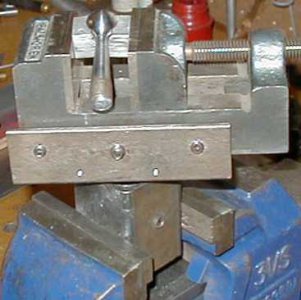

I have written up another pdf file on how I checker bolt knobs with tool I have made over the years. I will try to load this file in the DOWNLOADS section so all can view. This will show more info on how you can make the tools and gravers. I use a Ngraver shaft driven hand tool, but with a little practise you can use just a hammer and graver. I made my rotating vise out of 2 1/4 square steel with steel bearings in the base of 2 in. square tubing.