-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[Lathe] Chuck size?

- Thread starter PIKEMAN

- Start date

- Joined

- Sep 23, 2010

- Messages

- 619

Get both. I have both a 6 and an 8 on my SB10K. The 8" works great for odd or bigger parts...Bob

B

British Steel

Forum Guest

Register Today

Hi Pikeman,

On my 13-and-a-bit swing lathe, I have 8" and 5" 3-jaws, 10", 8" and 5" 4-jaws, but they also get swapped (the smaller ones) onto the rotary table now and then (a hassle, as the lathe has a D1-5" camlock spindle nose, have to take 'em off the backplates and onto a mounting plate fixture then indicate them true). A small 4-jaw can be a real benefit, as the large ones (like my 10") don't close up so well on small diameter parts - although a collet setup would be best for that, I suppose? Got one of those, too (gloat gloat)! Still looking for a 6-jaw self-centring to hold large thinwall tubing though...

For *really* big and oddly-shaped parts, there's no substitute for a faceplate as big as your lathe can swing - using T-nuts, bolts and clamps you can swing parts that reach to within a gnat's of the ways - if you don't have one, watch the auctions etc. as you'll find they're the only way to swing (e.g.) conrods for boring the journals, or cut trunnions and the like. I have a 12" faceplate, which is about as big as I'd want, and it only cost a fiver plus a set of camlock studs On a 10" lathe a 9" or 9&1/2" faceplate would be about right - you could always make one up if you had to, a piece of 1/2" or thicker plate angle-grindered to size with a threaded boss welded to the back and then faced/trued, with tapped holes for clamping, maybe?

On a 10" lathe a 9" or 9&1/2" faceplate would be about right - you could always make one up if you had to, a piece of 1/2" or thicker plate angle-grindered to size with a threaded boss welded to the back and then faced/trued, with tapped holes for clamping, maybe?

The only problems with faceplate work are balancing the work (e.g. weights bolted on) and you have to go *very* slowly and carefully - says he who's had a step block whizz past close enough to part his hair and embed itself in the ceiling when he didn't notice the gearbox was in the "high speed" range... Pay Attention, Dave! <slap>

Dave H. (the other one)

On my 13-and-a-bit swing lathe, I have 8" and 5" 3-jaws, 10", 8" and 5" 4-jaws, but they also get swapped (the smaller ones) onto the rotary table now and then (a hassle, as the lathe has a D1-5" camlock spindle nose, have to take 'em off the backplates and onto a mounting plate fixture then indicate them true). A small 4-jaw can be a real benefit, as the large ones (like my 10") don't close up so well on small diameter parts - although a collet setup would be best for that, I suppose? Got one of those, too (gloat gloat)! Still looking for a 6-jaw self-centring to hold large thinwall tubing though...

For *really* big and oddly-shaped parts, there's no substitute for a faceplate as big as your lathe can swing - using T-nuts, bolts and clamps you can swing parts that reach to within a gnat's of the ways - if you don't have one, watch the auctions etc. as you'll find they're the only way to swing (e.g.) conrods for boring the journals, or cut trunnions and the like. I have a 12" faceplate, which is about as big as I'd want, and it only cost a fiver plus a set of camlock studs

The only problems with faceplate work are balancing the work (e.g. weights bolted on) and you have to go *very* slowly and carefully - says he who's had a step block whizz past close enough to part his hair and embed itself in the ceiling when he didn't notice the gearbox was in the "high speed" range... Pay Attention, Dave! <slap>

Dave H. (the other one)

- Joined

- Sep 23, 2010

- Messages

- 619

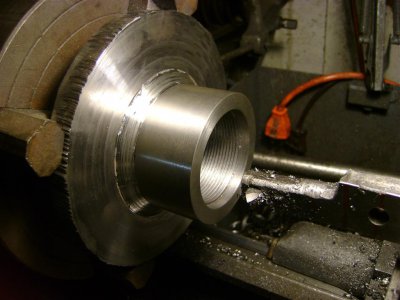

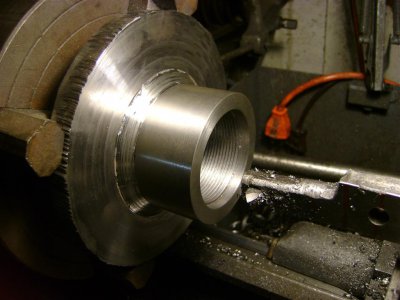

Here is why i have so many chucks. I do lots of custom work so you never know whats walking in the door. Here is some lathe chuck backplates i am making with my 8" chuck on my 10" lathe. Yes i could of used a faceplate but i want to cut to the edges and i can't have any bolt holes in it so the 8" comes out. It is perfect for my 10" lathe and i use it for lots of odd stuff...Bob

- Joined

- Sep 23, 2010

- Messages

- 619