- Joined

- May 27, 2016

- Messages

- 3,469

Does the riving knife plate that mounts close behind a circular saw blade have to be at least as thick as the saw blade cut width?

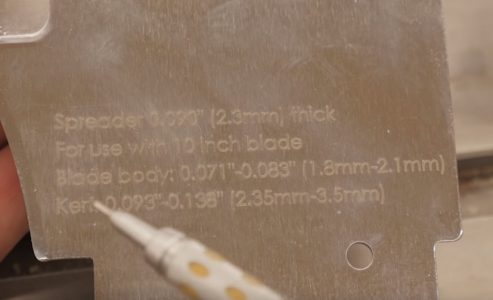

I have one of those reconfigurable aluminium saw table units with fence that has adapter mounts to fit most portable circular saws and routers underneath. I use it in "table saw" mode, presently using a claimed "thin" type saw blade. The teeth measure 2.12 mm wide (3/32") and the riving knife seems to be made of 2mm plated steel.

If I were to try a thicker stiffer blade, having kerf 2.8mm or more, do I have to install a thicker riving knife?

I have heard that a circular saw can suddenly "launch" the work across the room, or up out of the saw.

I have one of those reconfigurable aluminium saw table units with fence that has adapter mounts to fit most portable circular saws and routers underneath. I use it in "table saw" mode, presently using a claimed "thin" type saw blade. The teeth measure 2.12 mm wide (3/32") and the riving knife seems to be made of 2mm plated steel.

If I were to try a thicker stiffer blade, having kerf 2.8mm or more, do I have to install a thicker riving knife?

I have heard that a circular saw can suddenly "launch" the work across the room, or up out of the saw.