Mike,

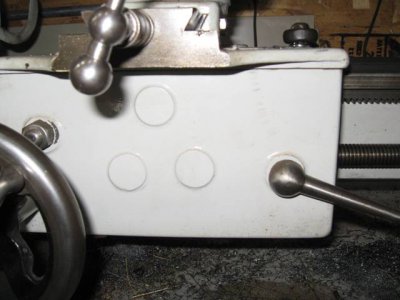

That looks like a nicely restored lathe. I'm not sure why you think it's a wood lathe. I don't recall ever seeing an ad for a wood lathe with a carriage, cross feed, compound and power feed.

However, this is the Atlas (and Craftsman) Forum. Although you are certainly welcome here, your quest for a steady rest and most other accessories as well as any machine specific questions will probably be better served if I move your thread to the Clausing Forum. Which I will do as soon as I write a little more. I do know that Atlas bought Clausing circa 1949 and then changed the company name to Clausing in the early 60's. And that we buy Atlas parts from Clausing today. But the Atlas and Clausing machines share no parts that I am aware of. And the owner of one brand isn't likely to know the answer to any machine specific questions about the other brand. Or worse, may think he does but be wrong.

Anyway, as you say it's a Clausing, I assume that it is but I don't recognize the model. That's what you need to know in order to start looking for a steady rest. There may be a few exceptions but in general one made by Brand X will not fit a lathe made by Brand Y, even though they have the same style bed ("V" or Flat) and are the same nominal size (i.e., 12x36). Once you know your lathe model number, unless someone on the Clausing forum knows the answer offhand, you can start by calling Clausing and asking them what it is. Then post a request in the Clausing Forum and also down in the Accessories and Tooling Wanted Forum which is near the bottom of the list of Forums.

Quick Change Tool Posts, on the other hand, are generic. You buy them and the holders for them by size. In most cases, they will come with a piece of thick flat bar threaded in the center for the stud or bolt that attaches them to the compound. You usually have to machine the bar into a T-nut to fit your compound T-slot because there is no standardization of T-slot size between various manufacturers. If you don't have a milling machine or a milling attachment and associated cutter holders to fit your lathe, you will need to take the bar along with your compound and the QCTP to a machine shop and have them fit it.

QCTP's and the holders that fit them come in several different sizes usually identified by one or the other of two systems. In ascending size, AXA (100 Series), BXA (200 Series, CXA (300 Series), etc. There is also a 0XA (may be 50 Series) but it's too small for a 12". Each size of holder best fits one size of cutter and and sometimes of boring bar. And will usually handle one size larger and smaller (at least of cutter). AXA is intended for 3/8" square cutters and 1/2" dia. boring bars. And will just hold 1/2" and 5/16" cutters. Etc. Most ads will say that the AXA fits 7" or 8" to 12" or 13". And BXA is for 12" to 15" or thereabouts. In my opinion, AXA is the best size for an Atlas 12" (there are two or three on the Atlas Forum who disagree with me and use a BXA). Aside from sales or specials, though, BXA and the cutters for it will cost more. But as I don't have any familiarity with your machine, you'd better get opinions from those who do.

In addition to size, there are several QCTP styles. Most on the market today, at least in what's apt to be your price range, are square and mount holders on two faces (one for turning and one for facing). There are two general ways in which the holder is tightened on the tool post, called piston and wedge. The wedge type is typically more expensive. And there are claims that it holds better and/or has better repeatability. I've had a Yuasa 100 Series piston style on my Atlas 3996 for 30+ years and have never had any trouble with it. You'll have to make up your own mind about that. The one thing that I strongly recommend you avoid, regardless of what you buy, is an aluminum tool post. They are a little cheaper (at least from the same vendor's list price sheet) than steel ones. But I wouldn't waste my money on one.

One other comment - most of the on-line vendors sell a set or kit including a tool post and one each of four or five types of holders at a savings over their list price for the individual pieces. Buy the kit. But also buy four or five more turning and facing holders (101) and one additional combination turning, facing and boring bar (102). Else within a week or two you will have to pay shipping again when you order some additional holders. The reason is that various common operations typically require various cutters. Although you can usually mount two cutters in one holder (usually one turning and one facing), if you start a job and then need to switch to a different type of cutter, and to do that you have to remove the first cutter from the holder and install the second and get it on center, you lose most of the benefits of the Quck Change and aren't much better off than with the lantern style tool holder.

Robert D.