Hi guys

Before I start, NO PICTURES ON THIS FIRST POST ARE MY OWN - they are from the net for reference only. I`ve been collecting pictures for years - if I can reference, I will do. I am posting for inspiration and ideas.

For many years I have wanted a clock wheel depthing tool. I expect being in this forum most will know but just incase, this tool allows you to correctly distance a wheel and pinion and then scribe the correct distance onto the frame.

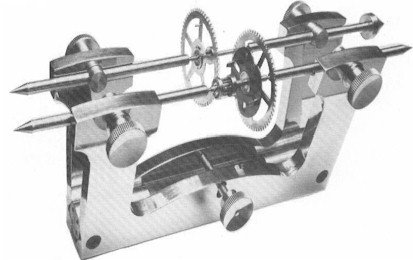

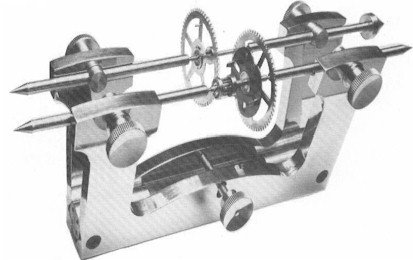

This is commercial clock depthing tool:

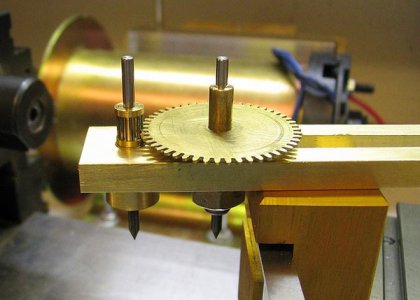

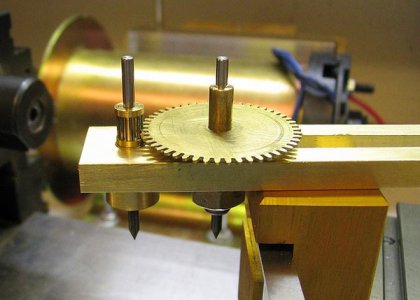

The runners sticking out of the end are then used to scribe a line to correct depth by turning the device vertical:

A cheap simple depthing tool can be made by plans described in several books I own, specifically by John Wilding and Colin Thorne. This is good for the majority of jobs, but at 30 years old, I`d like to keep this for a good time and would like to invest more time in to making a more traditional and more versatile tool.

From Dean and Deans Photographica:

There are loads and loads of homebrew depthing tools on the internet. My issue is that they rarely describe the machining process to ensure they maintain parallelism between the two split runners. Also, I`m not clear how the hinge is made or designed to ensure the two parts are held firmly without wobble but lose enough to be moved. I also don`t know how the spring is being applied to force the two halves together!!

Taking madmodding to the limits, here is a Perspex tool with elastic band as the spring. Made by John Prevatte:

And another, this one made from a door hinge by Jay Fortner:

This homemade design, unfortunately I don`t know the maker, has a slightly different clamp down top, rather than the V groove style holder for the runners:

Aluminium body, again I don`t know the maker but has a more homemade feel about it - no idea how it being sprung

This is smart spring method - I can clearly see how this is working but would you need to have a spring on each side to ensure even pressure is put on both sides otherswise the frame could twist, depending on the rigidy of the hinge:

Lots of food for thought! If you have any ideas or suggestions as to how to make one, I`d appreciate your input. The key is getting the runners parallel and a solid hinge between the two parts but allowing you to fine adjust the two.

I believe there is a full article: MEW no 8 Dec 91 jan 92 - if anyone has a copy of this article, I`d be really grateful!

I look forward to replies.

Chris

[/quote]

Before I start, NO PICTURES ON THIS FIRST POST ARE MY OWN - they are from the net for reference only. I`ve been collecting pictures for years - if I can reference, I will do. I am posting for inspiration and ideas.

For many years I have wanted a clock wheel depthing tool. I expect being in this forum most will know but just incase, this tool allows you to correctly distance a wheel and pinion and then scribe the correct distance onto the frame.

This is commercial clock depthing tool:

The runners sticking out of the end are then used to scribe a line to correct depth by turning the device vertical:

A cheap simple depthing tool can be made by plans described in several books I own, specifically by John Wilding and Colin Thorne. This is good for the majority of jobs, but at 30 years old, I`d like to keep this for a good time and would like to invest more time in to making a more traditional and more versatile tool.

From Dean and Deans Photographica:

There are loads and loads of homebrew depthing tools on the internet. My issue is that they rarely describe the machining process to ensure they maintain parallelism between the two split runners. Also, I`m not clear how the hinge is made or designed to ensure the two parts are held firmly without wobble but lose enough to be moved. I also don`t know how the spring is being applied to force the two halves together!!

Taking madmodding to the limits, here is a Perspex tool with elastic band as the spring. Made by John Prevatte:

And another, this one made from a door hinge by Jay Fortner:

This homemade design, unfortunately I don`t know the maker, has a slightly different clamp down top, rather than the V groove style holder for the runners:

Aluminium body, again I don`t know the maker but has a more homemade feel about it - no idea how it being sprung

This is smart spring method - I can clearly see how this is working but would you need to have a spring on each side to ensure even pressure is put on both sides otherswise the frame could twist, depending on the rigidy of the hinge:

Lots of food for thought! If you have any ideas or suggestions as to how to make one, I`d appreciate your input. The key is getting the runners parallel and a solid hinge between the two parts but allowing you to fine adjust the two.

I believe there is a full article: MEW no 8 Dec 91 jan 92 - if anyone has a copy of this article, I`d be really grateful!

I look forward to replies.

Chris

[/quote]