- Joined

- Jul 22, 2019

- Messages

- 29

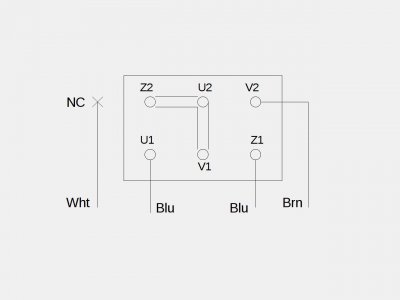

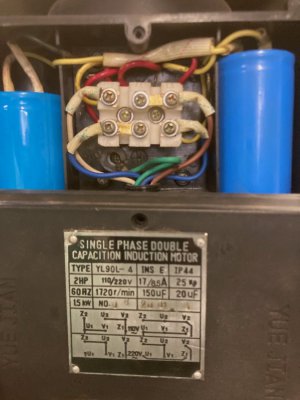

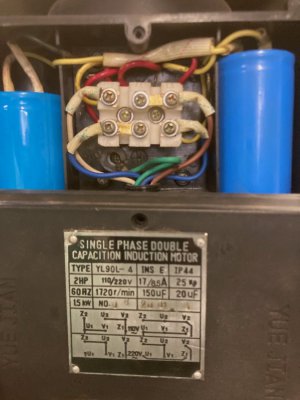

I have been tripping breakers occasionally on my mill-drill, so I got around to installing a 220V outlet. The plaque on the motor said 110//220V, and had a wiring diagram. However, when I took off the cover, the wiring diagram looked nothing like what I saw. I know a little bit about electric motors, and guess that the field gets reversed relative to the armature to reverse the motor, but I do not know where to start rewiring in this case. Is it possible that by reversing the motor they made it impossible to rewire for 220V? I could buzz out the wires, but not sure that would help me. The power goes to the reversing switch, and two cables (field and armature?) go from the reversing switch to the motor. It looks like the wiring comes in the bottom of the box, and then there are wires that go from the box to the motor at the top.

I could in theory install a 110V 30 amp circuit instead and bypass the problem, but I would have to run new wires, plus buy a new breaker, spool of 10ga wire, and a new outlet, so that would be quite a bit of work and expense. With less effort, I could make it a dedicated 110V 20 amp circuit, but not sure that would solve the tripping problem, as the other things on the previous circuit draw little power. My cheap clamp on ammeter says the circuit pulls 2 amps idling, presumably control circuits on stoves and garage door openers. The dedicated 110V circuit would make my wife happy, because I would not screw up the gas stove clock when the breaker trips.

Thanks in advance for your thoughts.

Richard

I could in theory install a 110V 30 amp circuit instead and bypass the problem, but I would have to run new wires, plus buy a new breaker, spool of 10ga wire, and a new outlet, so that would be quite a bit of work and expense. With less effort, I could make it a dedicated 110V 20 amp circuit, but not sure that would solve the tripping problem, as the other things on the previous circuit draw little power. My cheap clamp on ammeter says the circuit pulls 2 amps idling, presumably control circuits on stoves and garage door openers. The dedicated 110V circuit would make my wife happy, because I would not screw up the gas stove clock when the breaker trips.

Thanks in advance for your thoughts.

Richard

Last edited: