- Joined

- Jul 16, 2013

- Messages

- 43

Good day my fellow men in work shops.

I finally had a day open where I could go and relax , playing in the work shop!!!

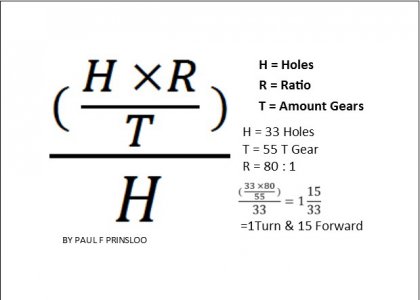

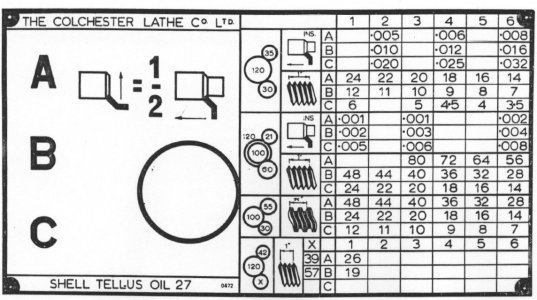

When I bought my Colchester Batham Lathe it only came with four gears a 35T , 100T ; 120T and a 30T and that gave me a limited options when it came to cutting threads. A closer look at the thread chart showed that if I had a 55T gear it would vastly improve my options.

and that gave me a limited options when it came to cutting threads. A closer look at the thread chart showed that if I had a 55T gear it would vastly improve my options.

I have been toying with the idea to make a gear in stead of buying one as I would be quite expensive to import a 55T gear for the lathe.

One challenge was that it has internal as well as external splines to fit the shaft on the lathe the second was that all the gears I saw on the net was made out of steel with a diameter of 90.2 mm also a size that is fairly hard to come by in our part of the world.

The last time I made a gear was for my pedestal drill and that was from nylon and that worked well so I decided to do the same for this project , worse case will the gear strip and that's ok with me for now..

First I had to find a piece of nylon , the only nylon that would be big enough.A piece of square scrap from a previous project found so I used that and got the center of it.

Next I chucked it up in the Four jaw and cut the internal hole to size (Sorry no picks). I wanted to keep the ID and OD as close as possible perpendicular with each other so I decided to make a quick "collet" for the gear that I can also transfer to the Dividing head.

That done I could mount the nylon to it and Cut the OD to size

Next step was to grind a piece of tool steel to the correct pitch for the gear ,

Close enough for me .....

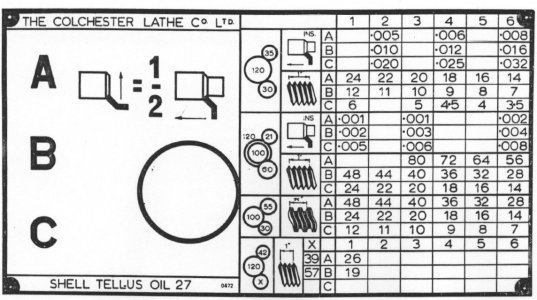

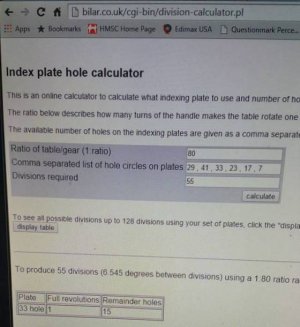

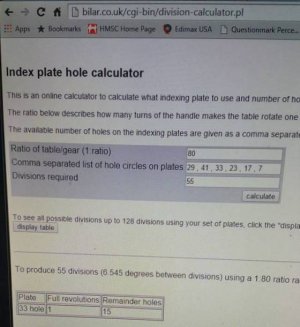

Then the fun and games began. I could not remember how to calculate the correct ratio for my dividing head and so I had to go to one of my best friends to help my and a couple of pages later I found a gem, thank you Google ! Here is a screen shot of the site that will calculate what ratios you could use on any type of ratio.

(This pick was also used in the shop)

Here is some picks of the setup and cutting of the outside gears ,

Next a closeup ,

Shot from the other side

Now I read or maybe it was in one of Rudy Kouhoupt videos that the sharper is one of the only tools that the home shop could utilize to cut internal gears and a while ago I made a tool holder to cut a key way and this came in handy again. It was only 8 splines so it went fairly quickly.

( I used a small weight to keep the clapper box from lifting too quickly when I did the internal cut)

( I used a small weight to keep the clapper box from lifting too quickly when I did the internal cut)

Here is the finished product ,

Here it is mounted ready for work. I will see if it hold but a few test runs did not show any foreseeable problems but time will tell ...

Hope you enjoyed it and found some useful info as well

Best regards

Paul

Ps.

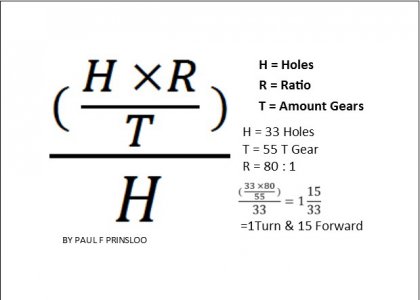

After it took some time to find the correct ratio I decided make a little " chart" with a formula that I laminated a will keep it with the dividing head for future reference. Here is it if some one would like to use it.

I finally had a day open where I could go and relax , playing in the work shop!!!

When I bought my Colchester Batham Lathe it only came with four gears a 35T , 100T ; 120T and a 30T

and that gave me a limited options when it came to cutting threads. A closer look at the thread chart showed that if I had a 55T gear it would vastly improve my options.

and that gave me a limited options when it came to cutting threads. A closer look at the thread chart showed that if I had a 55T gear it would vastly improve my options. I have been toying with the idea to make a gear in stead of buying one as I would be quite expensive to import a 55T gear for the lathe.

One challenge was that it has internal as well as external splines to fit the shaft on the lathe the second was that all the gears I saw on the net was made out of steel with a diameter of 90.2 mm also a size that is fairly hard to come by in our part of the world.

The last time I made a gear was for my pedestal drill and that was from nylon and that worked well so I decided to do the same for this project , worse case will the gear strip and that's ok with me for now..

First I had to find a piece of nylon , the only nylon that would be big enough.A piece of square scrap from a previous project found so I used that and got the center of it.

Next I chucked it up in the Four jaw and cut the internal hole to size (Sorry no picks). I wanted to keep the ID and OD as close as possible perpendicular with each other so I decided to make a quick "collet" for the gear that I can also transfer to the Dividing head.

That done I could mount the nylon to it and Cut the OD to size

Next step was to grind a piece of tool steel to the correct pitch for the gear ,

Close enough for me .....

Then the fun and games began. I could not remember how to calculate the correct ratio for my dividing head and so I had to go to one of my best friends to help my and a couple of pages later I found a gem, thank you Google ! Here is a screen shot of the site that will calculate what ratios you could use on any type of ratio.

(This pick was also used in the shop)

Here is some picks of the setup and cutting of the outside gears ,

Next a closeup ,

Shot from the other side

Now I read or maybe it was in one of Rudy Kouhoupt videos that the sharper is one of the only tools that the home shop could utilize to cut internal gears and a while ago I made a tool holder to cut a key way and this came in handy again. It was only 8 splines so it went fairly quickly.

( I used a small weight to keep the clapper box from lifting too quickly when I did the internal cut)

( I used a small weight to keep the clapper box from lifting too quickly when I did the internal cut) Here is the finished product ,

Here it is mounted ready for work. I will see if it hold but a few test runs did not show any foreseeable problems but time will tell ...

Hope you enjoyed it and found some useful info as well

Best regards

Paul

Ps.

After it took some time to find the correct ratio I decided make a little " chart" with a formula that I laminated a will keep it with the dividing head for future reference. Here is it if some one would like to use it.