- Joined

- Aug 29, 2019

- Messages

- 525

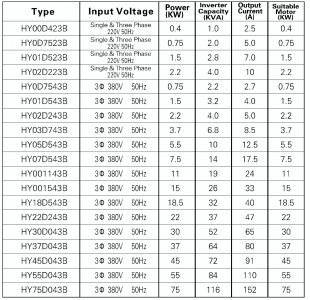

Well I sure did not know this and therefore bought one capable of driving 2hp but now I realize mine only is good for 2.5 amps. My motor pulls 6 amps at full load. Good thing I found this out because I just bought a MSC mill with 3 hp motor and will be buying another VFD for it. Ignorance is very expensive at least my ignorance of VFD's has proven to be. Beware when someone tells you that you need one that is 1.5 times the motor HP. That is only a half truth. Hopes this video is helpful to others. If I had of watched it before buying the 2 VFD's I already have I would not need to buy the third one. LOL If my mistake helps someone else then there has been value to my mistake. I am sure I have and will continue to reap value from others mistakes and experiences in all areas of machining. Enjoy the video. It is my objective to give back to this forum when I can because I surely have received much from it.