- Joined

- Feb 22, 2012

- Messages

- 924

I'll keep on keeping my fingers crossed

To be a bit more serious I think many tend to forget that when buying something used there is always a chance that there is no knowing how it's been treated or handled. Would you take the word of a used car saleman that the only owner was a little old lady that only used it to get to and from church?

Gordon

To me a caliper (singular) is an instrument where you can read the measurement result. Vernier, dial or digital. Calipers (plural) is the type where you feel your way and then take a reading from something else.

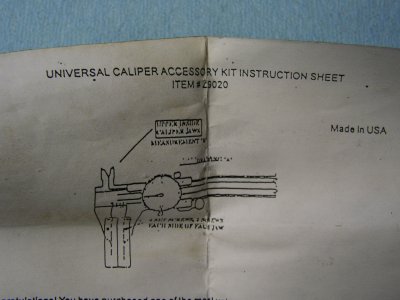

Both types are shown here:

http://www.google.dk/search?hl=da&s...urce=og&sa=N&tab=wi&ei=vJ1rT8GqNcbSsgahsMG6Ag

I'm not saying I'm right, just the way I personally keep them apart.

Thanks, and agreed on buying used. especially for precision tools there is a high chance of getting burnt, in this case I got it so cheap that the risk was worth taking. I'll keep on using it and hopeully the root cause of errors was the battery type. worst case, I'll be getting a (brand) new one this time.

As for the linguistic naming convention, I must say I was not aware of the difference, and it now make a lot of sense why these 2 similar yet different tools are called that way. the small details make all the difference sometimes. thanks for pointing that out.