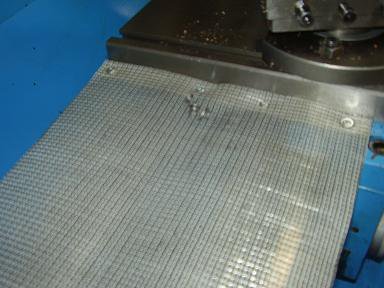

Today I’ve been working on a lathe bed protector, this is what I came up with: Mounted on the headstock, behind the chuck, is a piece of angle to which I welded a couple of brackets either end. I then shrunk a couple of slow speed self centering bearings into a couple of short pieces of 25mm PVC which I then shrunk onto the ends of a 240mm long piece of 19mm PVC pipe, I then mounted the assembly between the two brackets using ¼ “ bolts to locate inside the bearings.

To the 19mm PVC tube I riveted a piece of sarlon, then bolted a piece of aluminum angle to the front of the carriage and pop riveted the sarlon to the top of that. Roll up is controlled by a length of bricky’s string wound around the PVC pipe , the other end being attached to a weight, which slides inside a another piece of PVC pipe to keep it neat.

As the carriage is moved in, the weight rolls the sarlon around the 19mm PVC pipe keeping it taught. To remove any swarf, simply tap on the sarlon and the swarf bounces and slides off.

Obviously any hot swarf will melt the plastic, so, I’ll have to hunt around for something that won’t melt – I have a piece of oil impregnated canvas I might try.

There is about a 25mm gap between the sarlon and the bed, easily fixed by placing a roller guide on top of the sarlon to hold it down closer to the bed. I’m not too worried about chuck clearance though as I only intend on using it for milling and grinding operations.

To disconnect, simply wind the carriage in a little, lift the sarlon, undo the bolt (s) and allow the sarlon to wind up under the angle.

Video of the unit...

https://www.youtube.com/watch?v=H64c...ature=youtu.be

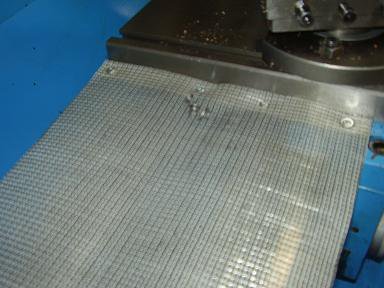

To the 19mm PVC tube I riveted a piece of sarlon, then bolted a piece of aluminum angle to the front of the carriage and pop riveted the sarlon to the top of that. Roll up is controlled by a length of bricky’s string wound around the PVC pipe , the other end being attached to a weight, which slides inside a another piece of PVC pipe to keep it neat.

As the carriage is moved in, the weight rolls the sarlon around the 19mm PVC pipe keeping it taught. To remove any swarf, simply tap on the sarlon and the swarf bounces and slides off.

Obviously any hot swarf will melt the plastic, so, I’ll have to hunt around for something that won’t melt – I have a piece of oil impregnated canvas I might try.

There is about a 25mm gap between the sarlon and the bed, easily fixed by placing a roller guide on top of the sarlon to hold it down closer to the bed. I’m not too worried about chuck clearance though as I only intend on using it for milling and grinding operations.

To disconnect, simply wind the carriage in a little, lift the sarlon, undo the bolt (s) and allow the sarlon to wind up under the angle.

Video of the unit...

https://www.youtube.com/watch?v=H64c...ature=youtu.be