Our son got me one of these to keep me busy during my upcoming forecasted downtime. Do not know how long it will be as of yet. Set it up and ran it two nights ago printing out the sample Buddha file and an Apex Bit driver handle which both came out good. Last night we printed a 3D articulated dragon for the grandkids. Came out good also using Elegoo gray PLA filament, ( he sent me a roll of that for starters also). A lot to learn about these machines. Lots of do’s and don’ts. Looks like they run on standard G-code, which I am familiar with from about 30 years ago. I will have to get up to speed on CAD if I want to print out parts for sand cast molds and such. Running some Flashforge Burnt Titanium tonight to print an articulated octopus. Machine looks promising for a low cost.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Elegoo Neptune 3 Pro

- Thread starter OTmachine

- Start date

- Joined

- Jan 7, 2016

- Messages

- 3,274

Congrats on the printer. I built a Voron 2.4 and use it extensively for projects in my shop.Our son got me one of these to keep me busy during my upcoming forecasted downtime. Do not know how long it will be as of yet. Set it up and ran it two nights ago printing out the sample Buddha file and an Apex Bit driver handle which both came out good. Last night we printed a 3D articulated dragon for the grandkids. Came out good also using Elegoo gray PLA filament, ( he sent me a roll of that for starters also). A lot to learn about these machines. Lots of do’s and don’ts. Looks like they run on standard G-code, which I am familiar with from about 30 years ago. I will have to get up to speed on CAD if I want to print out parts for sand cast molds and such. Running some Flashforge Burnt Titanium tonight to print an articulated octopus. Machine looks promising for a low cost.

The only G-code you will need to be concerned with will be the start and stop G-code, and you may not even need to know any of that. I was using Cura for my slicer but have propagated over to Orcaslicer.

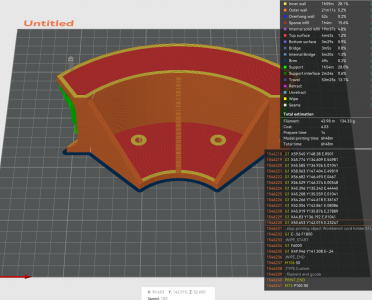

Below is a screenshot of a print I did recently. It is an extension cord holder that is mounted on the back side of my moveable workbench. If you look on the right side, you will see that there are about 1.5 million g-code lines. The slicer does all of that.

Attachments

- Joined

- Jun 29, 2014

- Messages

- 4,059

Congrats on the printer. I built a Voron 2.4 and use it extensively for projects in my shop.

The only G-code you will need to be concerned with will be the start and stop G-code, and you may not even need to know any of that. I was using Cura for my slicer but have propagated over to Orcaslicer.

Below is a screenshot of a print I did recently. It is an extension cord holder that is mounted on the back side of my moveable workbench. If you look on the right side, you will see that there are about 1.5 million g-code lines. The slicer does all of that.

Looking at that cord holder, I’ll bet you could print that on its end and use a lot less support material on the overhangs.

Sent from my iPhone using Tapatalk

- Joined

- Jan 7, 2016

- Messages

- 3,274

It might be possible, but I would need to re-design the end slightly so it sits flat on the bed. The webs would still need support.Looking at that cord holder, I’ll bet you could print that on its end and use a lot less support material on the overhangs.

Sent from my iPhone using Tapatalk

One thing I did was use trees for support. I am not 100% sold on that type of support. It may use less material, but it seems to take more time.

Got my first tangled filament error today. Going to try this method to recover 3/4 printed item. https://www.cnckitchen.com/blog/guide-resuming-a-failed-3d-print