- Joined

- Apr 14, 2014

- Messages

- 3,174

Now that things have settled down a bit I thought I'd try my hand at sharpening some end mills again. In the past I've been able to touch up the cutting ends on a number of different size and style end mills. I thought I'd progress onto some of the more difficult ones as time allows. To that end I purchased a lot of 10 1" 3 flute non center cutting mills a while ago. The mills were cheap and only meant to be used to improve my skills and techniques.

The mills have been abused and the cutting edges on some have been chipped as far as I back as 1/4". They're far beyond what's needed for a normal touchup. It looks like I'm going to have to grind them down past the existing damage before attempting any sharpening so here's my question. What do you use to recreate the secondary gash between the leading edge of one cutting tooth and the end gash on the heel of the cutting tooth in front of it?

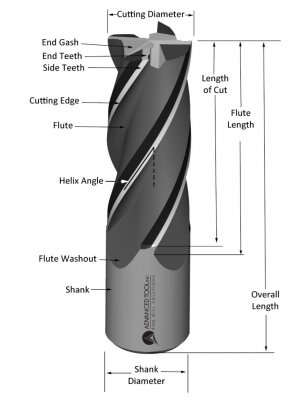

I'm thinking this process is often done with a thin cutoff disk since it doesn't appear nearly as finished as the relief behind the cutting edge. Here's a picture of a 4-flute mill for reference. The gash I'm referring to is just to the right of the arrow labeled "end teeth". Any suggestions as to what tool to use would be appreciated.

The mills have been abused and the cutting edges on some have been chipped as far as I back as 1/4". They're far beyond what's needed for a normal touchup. It looks like I'm going to have to grind them down past the existing damage before attempting any sharpening so here's my question. What do you use to recreate the secondary gash between the leading edge of one cutting tooth and the end gash on the heel of the cutting tooth in front of it?

I'm thinking this process is often done with a thin cutoff disk since it doesn't appear nearly as finished as the relief behind the cutting edge. Here's a picture of a 4-flute mill for reference. The gash I'm referring to is just to the right of the arrow labeled "end teeth". Any suggestions as to what tool to use would be appreciated.