- Joined

- Dec 27, 2012

- Messages

- 348

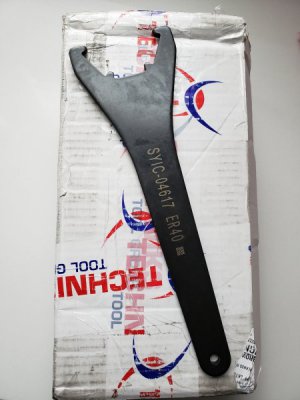

So I want to add a square hole to my er40 collet wrench. This will allow me to use a torque wrench. The collet wrench width and thickness is beefy enough that this subtraction shouldn’t weaken the wrench. I have another identical wrench that will not be modified so that can be used when not needing to torque it down.

I have a few questions.

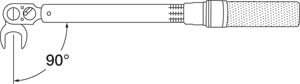

What size drive, 3/8” or 1/2”? Max torque for er40 Techniks nuts are 140ftlbs.

How would you create this square drive hole?

How does the distance of the square drive hole to the center of the nut effect my actual torque application compared to what is dialed in on my torque wrench?

The tightening of the collet nut will be in a CAT40 fixture. I think I will mount this fixture to a board and that will be clamped in a vise. Hopefully the torque application doesn’t tip the vise and stand over. But that’s another issue.

Thanks in advance for the help.

I have a few questions.

What size drive, 3/8” or 1/2”? Max torque for er40 Techniks nuts are 140ftlbs.

How would you create this square drive hole?

How does the distance of the square drive hole to the center of the nut effect my actual torque application compared to what is dialed in on my torque wrench?

The tightening of the collet nut will be in a CAT40 fixture. I think I will mount this fixture to a board and that will be clamped in a vise. Hopefully the torque application doesn’t tip the vise and stand over. But that’s another issue.

Thanks in advance for the help.