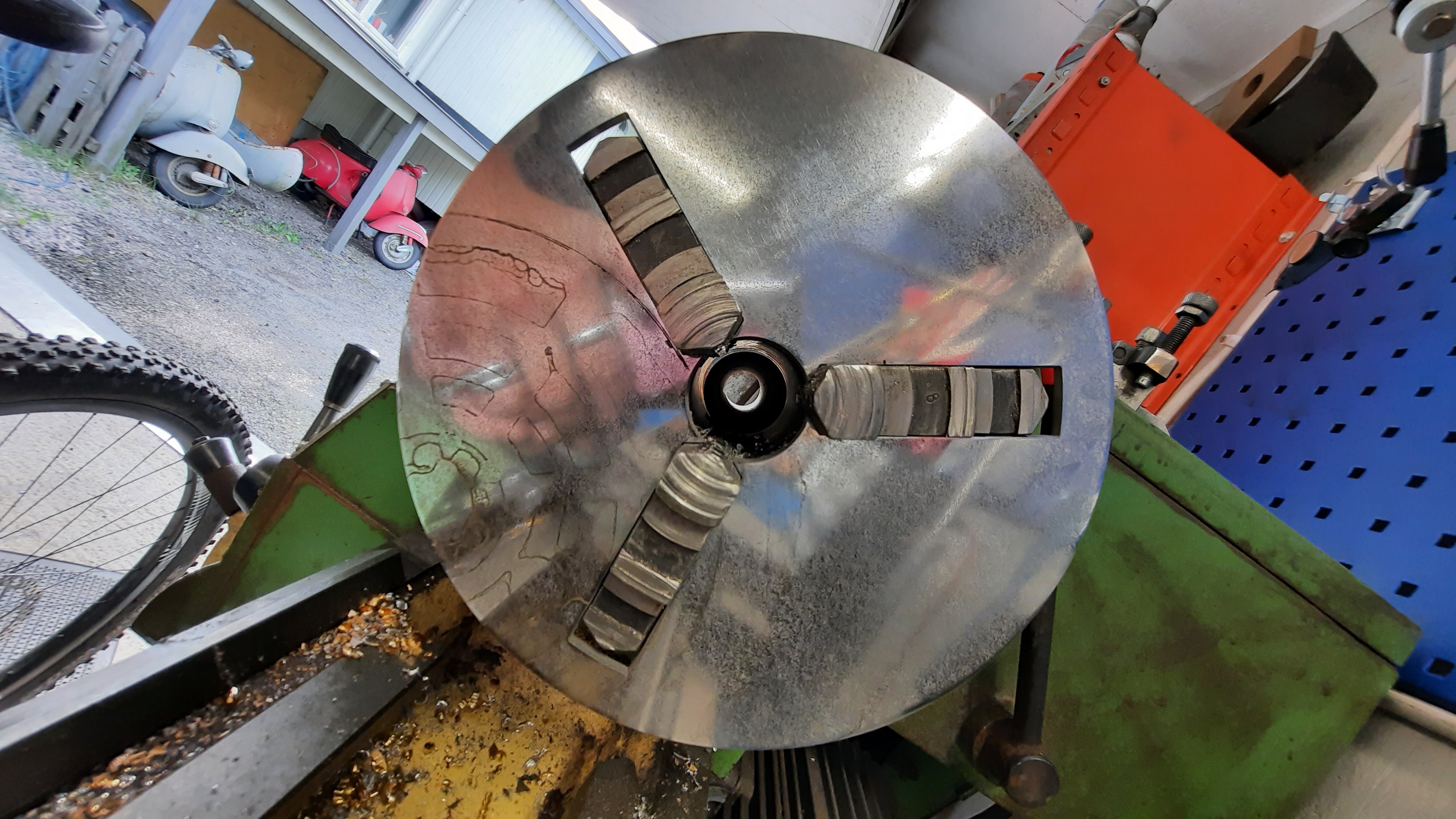

So I really need to grind the chuck on my lathe.

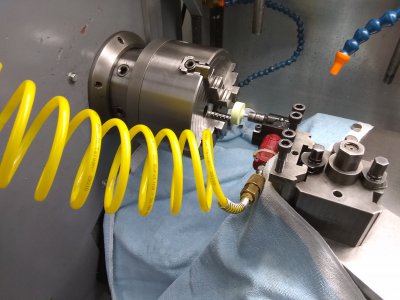

I made a holding plate today. And tomorrow I get to loan a grinder. But I have to do me a holder to get it up in the tool holder before I can use it. So hopefully next week. Any tips beforehand?

I made a holding plate today. And tomorrow I get to loan a grinder. But I have to do me a holder to get it up in the tool holder before I can use it. So hopefully next week. Any tips beforehand?

Never done this but been using grinding machines and fabricating holders allot before. But always easy to miss the obvious

Never done this but been using grinding machines and fabricating holders allot before. But always easy to miss the obvious