- Joined

- Mar 10, 2012

- Messages

- 1,368

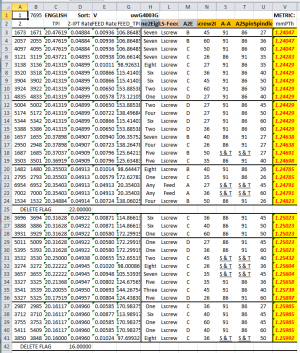

The 86/91 gear can be flipped with either the 91 0r the 86 on the inside. Mine came with the 91 in but I've used it both ways depending on the thread.

So I understand you correctly here, are you saying you can cut metric with either gear on the inside? Not talking about feeding, only threading. It was my understanding it had to be the 91T on the inside to cut metric. Thanks.