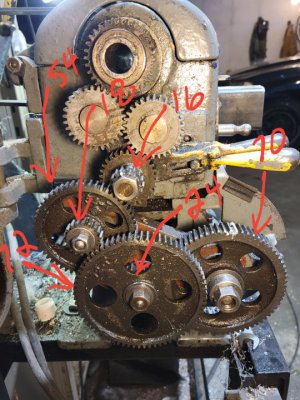

Here is the gear setup on my Logan 200 .... I presently have no additional gears...with this setup I am getting .002 inche per rev.... i would like to have a little more feed rate for rough cut... as thinking a 32 tooth in place of the 16, but unsure what the out come would be .004??

Thnks ken

Thnks ken