- Joined

- Nov 23, 2014

- Messages

- 2,606

Another Erector set reproduction part string. This one is for part number ‘CO’ lamp socket which was included in the largest sets from 1924 – 1932. Being used in just the largest sets means not a lot of sales volume, but the few I’ve made in the past have sold for $10 - $15 each.

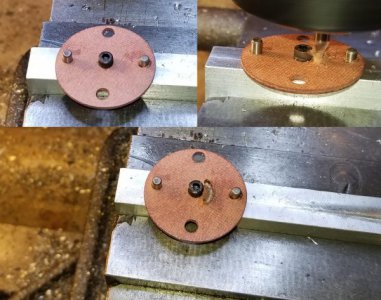

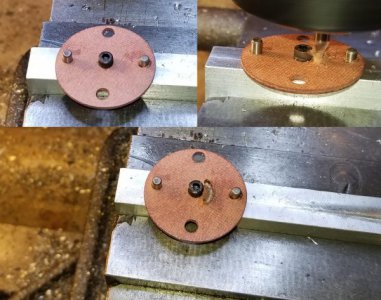

The “CO” has a fiber material base with a brass contact strip at the center and a coil of copper wire that the bulb screws into. The base is made from a pair of the fiber disks, probably to make it a little more substantial as the fiber material is pretty brittle.

The fiber disk has an arc 90 deg. long cut into it for an anti-rotation feature of the copper wire socket. I’ve made this before by hand drilling a series of holes, then filed down the peaks. Also drilled the end holes, mounted the disk on an arbor in the mill vise and manually rotated the disk to cut the arc. I planned on making a dozen or so of them so came up with some new fixturing.

Started by punching out the disk blanks (1 ¼” diameter) on the Roper Whitney #218 punch press. Then used a fixture to transfer punch the location of 4 holes. The “CO” have holes at 3, 6, 9 and 12 o’clock, opposite sides are 1/8” and 11/64”. The 1/8” holes are used for 4-40 screws, the 11/64” screw for 8-32 screws to fasten the base to a model. Punched the holes with a pair of RW No. 5 hand punches.

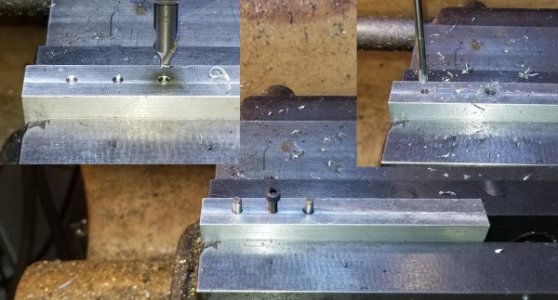

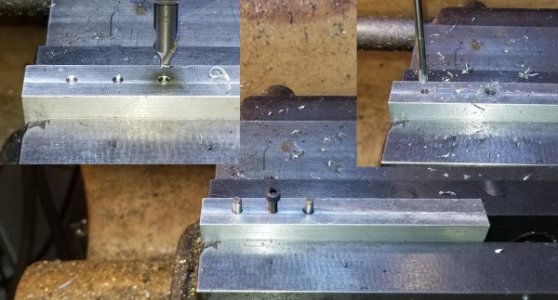

Made a holding fixture for my Bridgeport CNC mill for cutting the arc. Spot drilled, drilled and undersize reamed holes for a pair of 1/8” dowel pins. Drilled and tapped a 5-40 hole in the center for a hold down screw. In use I found the 1/8” pins held the disk down well, so didn’t end up using the screw.

Then made a mandrel on the lathe to wind the wire around. Measured the ID of a commercial E10 lamp socket with drill bits and went with that diameter minus a few thousandths for spring back after winding the coil of copper wire.

Made a holding block for the copper wire and mandrel. Used a piece of hex stock, center drilled and drilled holes for the copper wire end to slip into. I figured as long as the mill was set up I’d drill extra holes around the perimeter just in case I broke off the copper wire in one of the holes. After the mill work, went to the lathe to drill a center hole in the hex block that the mandrel would slip into.

In use, I strip a length of #14 copper wire and bend a 90 on the end. The end is slipped into one of the holes in the hex block and 4 winds are made around the mandrel. Mandrel is pulled from the hex block and a couple of bends are made using Vise Grips to hold the copper wire. Hard to see but I hand-scribed an arrow on the top of the block as a reminder for the wind direction. Yup, made a few LH thread sockets in the past . . .

I didn’t take photos of the brass contacts, but made those from 0.015” brass. Cut strips of brass on my shear and scribed in the hole location and length. The center tip has a tab bent up to contact the center of the bulb. Used a nibbler and Pexto flange bender to cut/bend up the center of the contact.

Again, not a big volume part, but gave me a chance to get in the shop and improve throughput should I need to make more. Thanks for looking.

Bruce

The “CO” has a fiber material base with a brass contact strip at the center and a coil of copper wire that the bulb screws into. The base is made from a pair of the fiber disks, probably to make it a little more substantial as the fiber material is pretty brittle.

The fiber disk has an arc 90 deg. long cut into it for an anti-rotation feature of the copper wire socket. I’ve made this before by hand drilling a series of holes, then filed down the peaks. Also drilled the end holes, mounted the disk on an arbor in the mill vise and manually rotated the disk to cut the arc. I planned on making a dozen or so of them so came up with some new fixturing.

Started by punching out the disk blanks (1 ¼” diameter) on the Roper Whitney #218 punch press. Then used a fixture to transfer punch the location of 4 holes. The “CO” have holes at 3, 6, 9 and 12 o’clock, opposite sides are 1/8” and 11/64”. The 1/8” holes are used for 4-40 screws, the 11/64” screw for 8-32 screws to fasten the base to a model. Punched the holes with a pair of RW No. 5 hand punches.

Made a holding fixture for my Bridgeport CNC mill for cutting the arc. Spot drilled, drilled and undersize reamed holes for a pair of 1/8” dowel pins. Drilled and tapped a 5-40 hole in the center for a hold down screw. In use I found the 1/8” pins held the disk down well, so didn’t end up using the screw.

Then made a mandrel on the lathe to wind the wire around. Measured the ID of a commercial E10 lamp socket with drill bits and went with that diameter minus a few thousandths for spring back after winding the coil of copper wire.

Made a holding block for the copper wire and mandrel. Used a piece of hex stock, center drilled and drilled holes for the copper wire end to slip into. I figured as long as the mill was set up I’d drill extra holes around the perimeter just in case I broke off the copper wire in one of the holes. After the mill work, went to the lathe to drill a center hole in the hex block that the mandrel would slip into.

In use, I strip a length of #14 copper wire and bend a 90 on the end. The end is slipped into one of the holes in the hex block and 4 winds are made around the mandrel. Mandrel is pulled from the hex block and a couple of bends are made using Vise Grips to hold the copper wire. Hard to see but I hand-scribed an arrow on the top of the block as a reminder for the wind direction. Yup, made a few LH thread sockets in the past . . .

I didn’t take photos of the brass contacts, but made those from 0.015” brass. Cut strips of brass on my shear and scribed in the hole location and length. The center tip has a tab bent up to contact the center of the bulb. Used a nibbler and Pexto flange bender to cut/bend up the center of the contact.

Again, not a big volume part, but gave me a chance to get in the shop and improve throughput should I need to make more. Thanks for looking.

Bruce