Need a recommendation for a good milling vise. I have a used but nice shape Kurt D675 but it's just simply too large for my table. I can mount it, but on a mill the size of a G3102 I lose way too much Y travel. The back of the vise hits the column before I can get the tool over the work a lot of times. I can mount it sideways for some things & do that whenever possible.

I also have the cheapie milling vise that came with the machine that's a good size for it, but it behaves like a cheap import vise & really lifts the work as it clamps. Setups take forever.

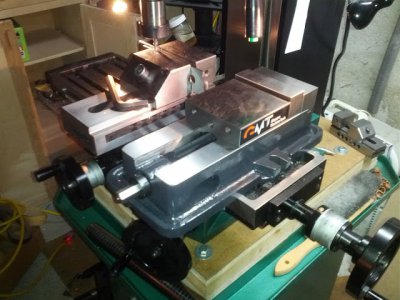

Mine is a different brand, but exact same thing as this. My table is slightly larger at 6 5/8 x 29:

I really like the Kurt & want to find something that works every bit as well, but smaller. I don't think Kurt makes one, but someone has to. I'm all for cheaping out on tooling, but not for a vise - not worth saving a few bucks on something I have to fight with nonstop. I sit work on parallels, tighten vise, give a whack with a deadblow, tighten a touch more & I'm ready to go with the Kurt. A dial indicator shows it flat all the way across. It's literally 15 min of tinkering to get to that same point with the cheapie vise. The Kurt also HOLDS the work solidly. With the cheapie vise, the parallel against the movable jaw will work lose at some point - enough that it can freely slide out.

What are some good brands to look for?

I also have the cheapie milling vise that came with the machine that's a good size for it, but it behaves like a cheap import vise & really lifts the work as it clamps. Setups take forever.

Mine is a different brand, but exact same thing as this. My table is slightly larger at 6 5/8 x 29:

I really like the Kurt & want to find something that works every bit as well, but smaller. I don't think Kurt makes one, but someone has to. I'm all for cheaping out on tooling, but not for a vise - not worth saving a few bucks on something I have to fight with nonstop. I sit work on parallels, tighten vise, give a whack with a deadblow, tighten a touch more & I'm ready to go with the Kurt. A dial indicator shows it flat all the way across. It's literally 15 min of tinkering to get to that same point with the cheapie vise. The Kurt also HOLDS the work solidly. With the cheapie vise, the parallel against the movable jaw will work lose at some point - enough that it can freely slide out.

What are some good brands to look for?