- Joined

- Jan 20, 2018

- Messages

- 5,675

A few months ago a friend gave me some taper shank endmills. At first I thought they were MT2, but closer examination revealed that they were B&S 7 taper. After checking eBay to be sure I wouldn't be able to retire comfortably if I sold them, I decided to turn the shanks straight so I could hold them in a collet.

The first one went well. It was hard, but only somewhere about Rc 45. No problem.

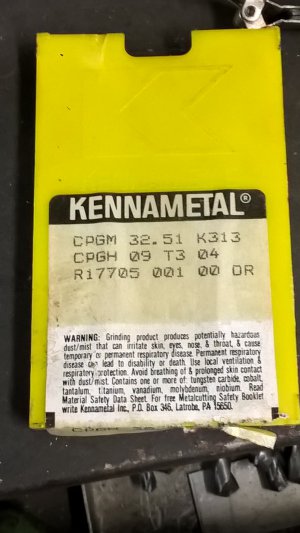

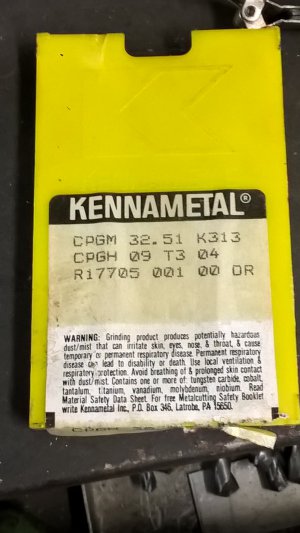

The rest were another matter, a file wouldn't even make a mark. I had been using a Chinese CCMT insert. It cut, but chipped on the first pass. I switched to a different tool, which was loaded with an insert from a pack I had inherited.

I was able to turn the remaining 3 endmills with one corner, though it showed some wear after the first pass.

After finishing the turning, I decided to try to part the shanks to length. Not having a carbide parting tool, I tried HSS.

It wouldn't even make a scratch. I ended up plunging the turning tool to make a groove and will cut them off when I get a cut-off wheel for my angle grinder.

It was fun.

The first one went well. It was hard, but only somewhere about Rc 45. No problem.

The rest were another matter, a file wouldn't even make a mark. I had been using a Chinese CCMT insert. It cut, but chipped on the first pass. I switched to a different tool, which was loaded with an insert from a pack I had inherited.

I was able to turn the remaining 3 endmills with one corner, though it showed some wear after the first pass.

It wouldn't even make a scratch. I ended up plunging the turning tool to make a groove and will cut them off when I get a cut-off wheel for my angle grinder.

It was fun.